Filament sensor issues? (possible fix)

So I've had an MK4 for almost two months.. about a month into it I had a filament run out and from that point on my filament sensor wouldn't properly detect filament. I wasn't able to calibrate the sensor and had to leave it disabled. I could get it to detect filament if I really jiggled the filament around so I was guessing I had some debris in there somewhere.

I went through all the steps with support to troubleshoot and they wanted me to wait for the assembly manual so I could open things up. I reached out to chat today since the manuals are now available and the agent had an additional troubleshooting step that I hadn't tried. On the extruder there is a small hole. I unloaded the filament, opened the idler door and blew compressed air into that hole as I poked a piece of filament in and out of the filament path. Looking at the manual, it looks like the hole is meant for this very purpose. In any case, it worked and my filament sensor is working again. Just wanted to share in case it helps anyone else out.

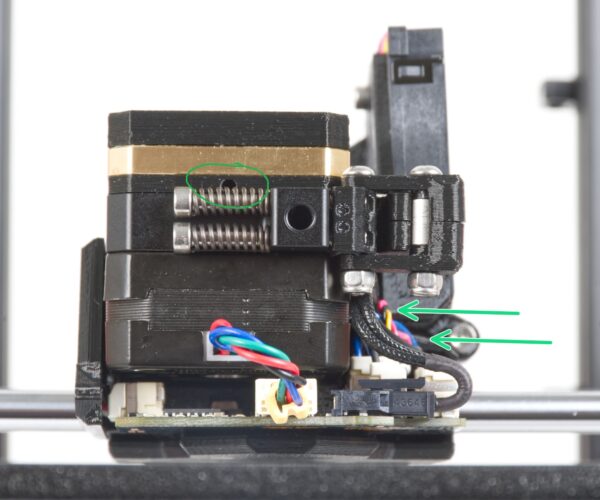

Hole circled in green:

RE: Filament sensor issues? (possible fix)

Thanks for posting this! My filament sensor pretty much just stopped working. I may have had a runout, not sure. but now even swapping filament is a hassle because it does not detect when the old filament has been unloaded or the new one loaded, and there is no way to bypass is on the screen. I'll try what you said tonight, and hopefully have a properly working printer again.

RE: Filament sensor issues? (possible fix)

Thanks for this for sure! I had the same issue about 15 mins ago due to this. Was printing out old filament, prolly too much dust on it that caused the sensor to fail. Canned air and some in-n-out in the path and all good now! Thanks!

RE:

Thanks a lot, that saved my day! Had the same issue. It started after printing carbon filament. Seems like there were a lot of fibres inside, clogging the sensor! The new magnetic filament sensor seems to be less resilient than expected...

I went through all the steps with support to troubleshoot and they wanted me to wait for the assembly manual so I could open things up. I reached out to chat today since the manuals are now available and the agent had an additional troubleshooting step that I hadn't tried. On the extruder there is a small hole. I unloaded the filament, opened the idler door and blew compressed air into that hole as I poked a piece of filament in and out of the filament path. Looking at the manual, it looks like the hole is meant for this very purpose. In any case, it worked and my filament sensor is working again. Just wanted to share in case it helps anyone else out.

RE: Filament sensor issues? (possible fix)

😢📖💨😄🙏👍🙇♂️

On a more technical note, the filament sensor status (Info/Sensor Info)was reporting around 1.40m with filament inserted and 670k with no filament ("INS" displayed in both cases). A couple very gently puffs from a can of compressed air (with the tube bent so I could keep the can vertical and not dump liquified gas into it and possible crack parts!) and it's reading 1.5m with filament ("INS") and as little as 50k without ("NINS"). (It reports jittery and inconsistent values to single digits, so I rounded.) Inserting filament very slowly while watching the display, I think that the transition point is around 620,000.

I don't know whether the printer had detected the problem or if triggering the filament sensor while monitoring it turned it off, but I had to disable and reenable the filament sensor before it would auto-load again. (Indeed, auto-loading would have been annoying while I was playing with the sensor readings.)

RE: Filament sensor issues? (possible fix)

😢📖💨😄🙏👍🙇♂️

On a more technical note, the filament sensor status (Info/Sensor Info)was reporting around 1.40m with filament inserted and 670k with no filament ("INS" displayed in both cases). A couple very gently puffs from a can of compressed air (with the tube bent so I could keep the can vertical and not dump liquified gas into it and possible crack parts!) and it's reading 1.5m with filament ("INS") and as little as 50k without ("NINS"). (It reports jittery and inconsistent values to single digits, so I rounded.) Inserting filament very slowly while watching the display, I think that the transition point is around 620,000.

I don't know whether the printer had detected the problem or if triggering the filament sensor while monitoring it turned it off, but I had to disable and reenable the filament sensor before it would auto-load again. (Indeed, auto-loading would have been annoying while I was playing with the sensor readings.)

did you blow the air down the cleanout hole or the filament path?

RE: Filament sensor issues? (possible fix)

I hit this issue on my MK4 after only a few months of printing (stats: 20days print time, 1.7km filament).

At first I tried the same trick as described above. A tiny white piece of filament came out at one point and I was able to get it working. But it lasted only one or two filament changes. So I decided to take the Nextruder apart.

(using the naming as described in https://help.prusa3d.com/guide/5-nextruder-assembly_434014 )

Removing the "Prusa ball holder" was a bit tricky. I used a piece of filament fed through the regular input to push the Steel ball in. Then I used some pliers to wiggle the holder out enough for me to get a grip with my nails. See the photo below of what came out (2.5mm hex key for scale). Assembled it all back together, recalibrated and all good now.

For those needing to take apart extruder, a couple hints:

1. Start with filament unloaded

2. Make sure you have the "PG assembly adapter" handy

3. Consider re-printing the "Main plate", if you have PETG on hand. Mine OEM piece was looking like a bit like rough printout. The replacement turned out noticeably nicer looking.

4. After assembling it together, use the proper steps from Nextruder assembly manual, but don't tighten the screws

5. First thing after powering it on, go to menus and run Nextruder calibration (follow the steps) and then Filament sensor calibration.

RE:

did you blow the air down the cleanout hole or the filament path?

What, that wasn't clear from the string of emoji? 😉 I pretty much blew air everywhere that seemed relevant.... mostly the filament path because it's easiest, but I tried to get a fair number of puffs into the cleanout hole, too. Thank you very much for taking the time to point it out so clearly.

(Sorry for the slow reply. I will check to see if this forum does email notifications.)

RE: Filament sensor issues? (possible fix)

i got same issue after + - 600 meters of filament... i must open it and clean.... this is extremly anoyng. now i must clean it second time, but blowing with air is not working for me. this need better solution for cleaning... maybe some kind of cutout on extruder gearbox cover, or something

RE:

Thanks! The compressed air worked for me! This occured after the filament ended (during print) and printer initiated reload. I might have removed it too fast though.

RE: Filament sensor issues? (possible fix)

After new sefttest, filamet sensor stopped working/calibration failed. It was working fine before that. With 5,0,1 it doesnt register when i press in the filament. But when i go to sensor it shows 1478844 whitout filament and 1838750 with filament pushed in. So sensor is working but keeps failing. Tried updating to 5,1,0 beta and doing calibration again. It sees the filament and i get the green tick. But when i press the knob, it failes?

Tryed compressed air in small hole, no help.

RE: Filament sensor issues? (possible fix)

Well, did the only thing that I should have startet with. Took the filament sensor apart. And behold, I had 2 magnets between spring and ball!!!!! My fault. How come it have worked until now, I don`t know. Did the filament calibration and all worked out fine.

RE: Filament sensor issues? (possible fix)

Thanks for this tip. I didn't have any compressed air so I blew into the hole and poked some filament into the filament path. This fixed the problem immediately.

Thanks again for posting

RE: Filament sensor issues? (possible fix)

Hey can you elaborate where these magnets are?

RE: Filament sensor issues? (possible fix)

So I've had an MK4 for almost two months.. about a month into it I had a filament run out and from that point on my filament sensor wouldn't properly detect filament. I wasn't able to calibrate the sensor and had to leave it disabled. I could get it to detect filament if I really jiggled the filament around so I was guessing I had some debris in there somewhere.

I went through all the steps with support to troubleshoot and they wanted me to wait for the assembly manual so I could open things up. I reached out to chat today since the manuals are now available and the agent had an additional troubleshooting step that I hadn't tried. On the extruder there is a small hole. I unloaded the filament, opened the idler door and blew compressed air into that hole as I poked a piece of filament in and out of the filament path. Looking at the manual, it looks like the hole is meant for this very purpose. In any case, it worked and my filament sensor is working again. Just wanted to share in case it helps anyone else out.

Hole circled in green:

Dude thanks a lot, saved my 8 hour print😍

RE: Filament sensor issues? (possible fix)

Air to hole didn't work for me.

I followed these instructions to remove the filament sensor and the tiniest spec of plastic cam out. About the size of an Atom probably, that little piece disabled my sensor completely:/

anyway this is the link with instructions that fixed it for me 🙂

https://help.prusa3d.com/de/article/nextruder-filamentsensor-core-one-mk4-s-mk3-9-s-xl_465702

RE: Filament sensor issues? (possible fix)

Thank you Brutus! This fixed my sensor issue on the MKS4 (also a couple of months old) !

So I've had an MK4 for almost two months.. about a month into it I had a filament run out and from that point on my filament sensor wouldn't properly detect filament. I wasn't able to calibrate the sensor and had to leave it disabled. I could get it to detect filament if I really jiggled the filament around so I was guessing I had some debris in there somewhere.

I went through all the steps with support to troubleshoot and they wanted me to wait for the assembly manual so I could open things up. I reached out to chat today since the manuals are now available and the agent had an additional troubleshooting step that I hadn't tried. On the extruder there is a small hole. I unloaded the filament, opened the idler door and blew compressed air into that hole as I poked a piece of filament in and out of the filament path. Looking at the manual, it looks like the hole is meant for this very purpose. In any case, it worked and my filament sensor is working again. Just wanted to share in case it helps anyone else out.

Hole circled in green:

RE: Filament sensor issues? (possible fix)

Thank you this worked for me! Filament ran out mid print and it still says it detected it even though there was none.

RE: Filament sensor issues? (possible fix)

Thanks for the helpful steps above!

After building a MK4S kit over the past few days the filament sensor would not detect filament during the initial calibration. In my case the magnet in the filament sensor had rotated 90 degrees and the spring no longer actuated - quick fix once I found the culprit!

RE: Filament sensor issues? (possible fix)

Thank you that fixed my problem.