Slic3r: gap in thin wall

I want to print a thin walled part (0.8mm) with a 0.6mm nozzle but Slic3r leaves a gap from a thin wall to filled neighbor. If the neighbor is hollow there is no gap. All Extrusion width are set to 0.8mm. Detect thin walls is on.

This happens with the latest stable and also Slic3rPE-1.42.0-Beta

As it is a large part I want to print it with just one perimeter.

Any ideas?

Manfred

Preview

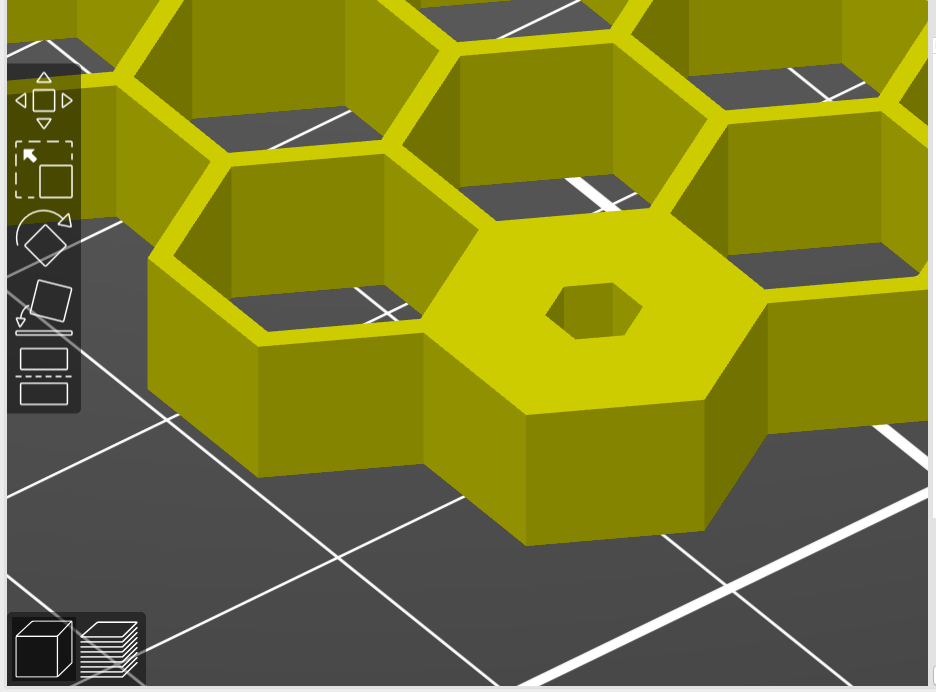

3D editor view

Re: Slic3r: gap in thin wall

You can find the part at thingiverse: https://www.thingiverse.com/thing:3457603

Its a 3D-printed house for mason bees (or "Mauerbienen" here in Austria).

With 0.4mm Nozzle and two perimeters it takes about 22 hours to print, with 0.6mm nozzle and one single wall it should take about 7 hours.

Does anybody know if this gap is a bug or just the result of my setting?

Re: Slic3r: gap in thin wall

Turn on random seams and see if there is any change.

Re: Slic3r: gap in thin wall

What's your extrusion with?

You can also try if activating detect thin walls helps

Fabian

Re: Slic3r: gap in thin wall

Thank you Fabian and Frio!

@ Frio: I tested all possible seam settings, no change..

@ Fabian: as written in the first post extrusion width is 0.8mm and detect thin walls is on. With two perimeters there is no gap but printing time is more than 22 hours and I want to print a larger number of these bee houses...

Manfred

Re: Slic3r: gap in thin wall

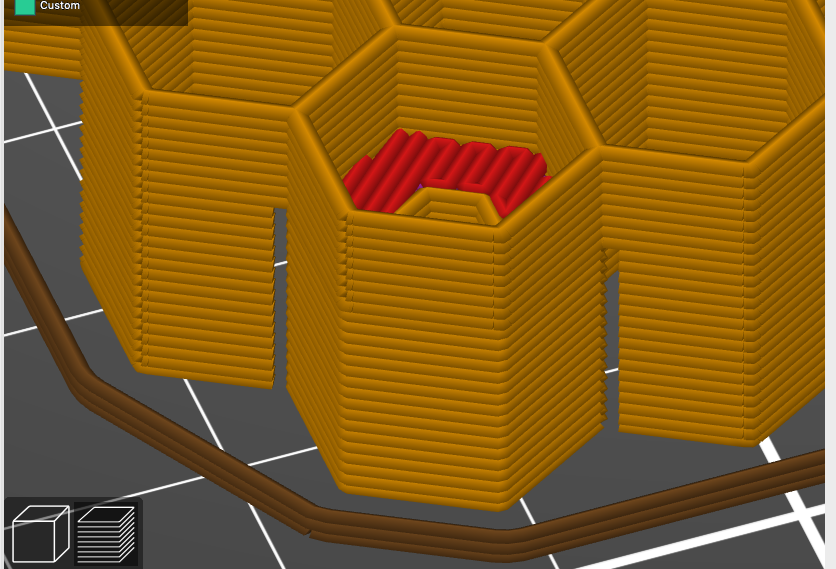

Very weird. I messed around with this when I got home from work but to no avail. I believe you'll need to use 'Detect thin walls' or you'll potentially end up with a blobby mess as traces overlap too much but using it is where things go bad. It seems the geometry of a bunch of connected single wall hexagons is throwing Slic3r for a loop as it can't determine how to connect them, or is miscalculating the distance. Interestingly this is only happening on the four "corners" of the part. None of the inner hexagons exhibit this which leads me to believe it has something to do with he fact that the corner hex's are not detected as thin walls (as they have infill that can adjust) but all the other hexagons are detected, which are thin walled and can't be adjusted.

Just for kicks I ran it through Netfabb and Meshmixer with no change.

Have you tried a different slicer?

Honestly, if you want to get this printed with Slic3r I would just use two perimeters and an appropriate nozzle and extrusion width. I would also file a bug report over at Github.

Good luck.

Re: Slic3r: gap in thin wall

Just tried slicing in KISS. At 0.8mm extrusion width, the honeycombs are not sliced (too thin), but they do appear to slice well at 0.6mm extrusion width.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

Re: Slic3r: gap in thin wall

Hi Manfred

Sorry, I skipped the part with you extrusion with.

I was able to reproduce it with you settings and it works when you disable detect thin walls.

btw: cool project!

Fabian

Re: Slic3r: gap in thin wall

Thank you for all replies!

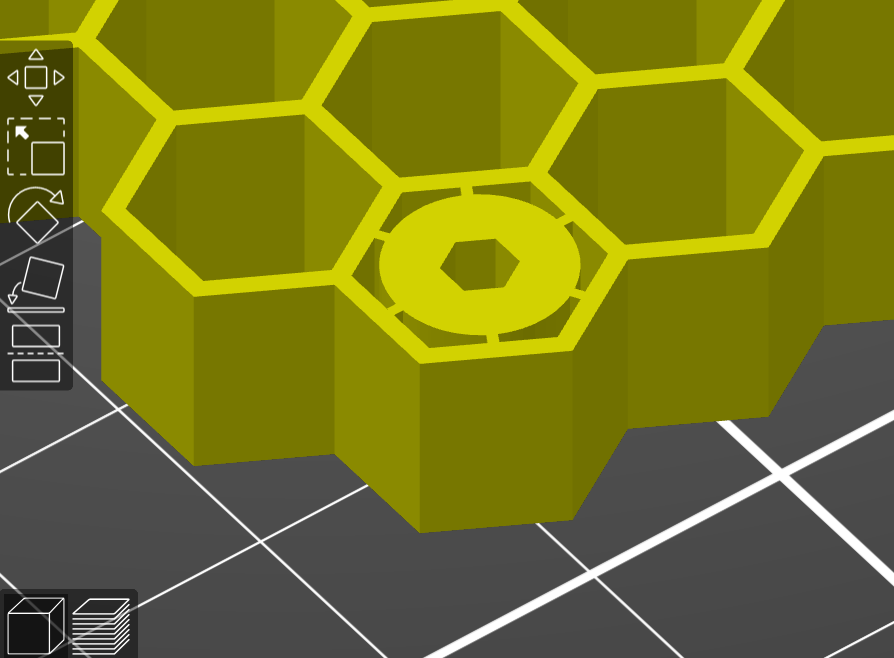

As I had no luck with other slicers and a lot testing with different settings I finally changed the design.

The hexagon of the filled part is now a thin wall too and for the screw hole I made a solid part with thin connections to the hexagon.

Slicing was successful and I finally printed the part with 0.8mm nozzle, 0.7mm layers and PLA in 7 hours ( with 0.4mm nozzle it took 22 hours...)

Manfred