Prusa PCCF usage

Good morning

As I need to print a fan shroud my employer ordered me a roll of Prusa PCCF to test...

Now the big question(s) as I just used PC in the past:

- What is a good printing surface for it? Can I use my rough PEI surfaces or FR4 sheets?

- How do you switch between such a high temperature filament to another one like ASA/PLA?

- Would a M2 0.4mm nozzle do well with PCCF?

- Anything else to watch for?

thanks in advance

richard

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE: Prusa PCCF usage

Stupid question, what is PCCF?

RE: Prusa PCCF usage

Ah sorry...

It's the Prusa PC filament with carbon fibre in it....

But so far it's sticking to the Qidi i-Mate S printing bed for almost three hours now 😉

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE: Prusa PCCF usage

- What is a good printing surface for it? Can I use my rough PEI surfaces or FR4 sheets?

- How do you switch between such a high temperature filament to another one like ASA/PLA?

- Would a M2 0.4mm nozzle do well with PCCF?

- Anything else to watch for?

I have only experience with regular PC-Blend. I print it on PEI surface together with Magigoo PC. This solves any issues with premature 1st layer detachment, even without brim and also enables were easy realease once cooled down. The Magigoo PC is also very easily removable by simply rinsing with water and wiping dry with a clean paper towel.

I usually flush the PC out with a bit of ASA or ABS at the lower end of the PC blend temp range. I don't think it should be too much of a problem to go down even further. Just try it out, if it skips steps or jams increase the hotend temperature. Not sure if the CF makes that trickier.

Sorry, can't give insight in regards to the Nozzle. My gut feeling is that it should work with a 0.4 mm nozzle but you definitely need a hardened one of course. I don't know how prone PCCF is to clogging, if you have a lot of problems, maybe going up to 0.5 or 0.6 mm is an option.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Prusa PCCF usage

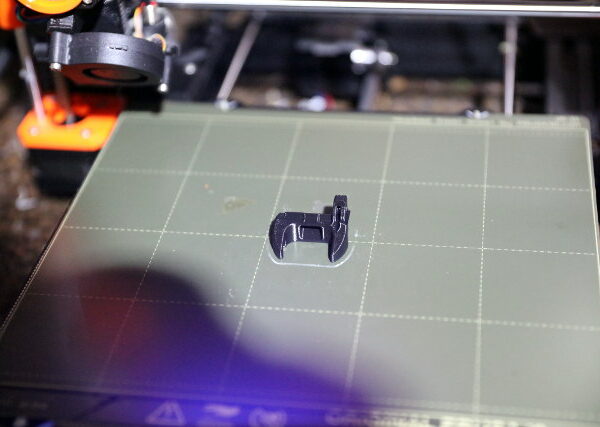

Wow..after 5 hours and 13 minutes the print is finished with a M2 0.4mm hardened nozzle on my i-Mate S (using the extended temp. extruder and full metal hotend). And it could be easily removed as well with bending the flex plate....dunno what Qidi is using here as a surface....

So no clogging/extruder skipping occurred..

The last time I tried a CF blend my other printer couldn't get anything out of the 0.6mm nozzle at all...

Not the last roll Prusa PCCF I will use 🙂

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE:

- What is a good printing surface for it? Can I use my rough PEI surfaces or FR4 sheets?

- How do you switch between such a high temperature filament to another one like ASA/PLA?

- Would a M2 0.4mm nozzle do well with PCCF?

- Anything else to watch for?

I have only experience with regular PC-Blend. I print it on PEI surface together with Magigoo PC. This solves any issues with premature 1st layer detachment, even without brim and also enables were easy realease once cooled down. The Magigoo PC is also very easily removable by simply rinsing with water and wiping dry with a clean paper towel.

I usually flush the PC out with a bit of ASA or ABS at the lower end of the PC blend temp range. I don't think it should be too much of a problem to go down even further. Just try it out, if it skips steps or jams increase the hotend temperature. Not sure if the CF makes that trickier.

Sorry, can't give insight in regards to the Nozzle. My gut feeling is that it should work with a 0.4 mm nozzle but you definitely need a hardened one of course. I don't know how prone PCCF is to clogging, if you have a lot of problems, maybe going up to 0.5 or 0.6 mm is an option.

As well, I have no experience with PCCF, but I've used Prusament PC Blend with good results.

My first PC Blend print was a remixed fan shroud, as the original had started drooping after a long run of ABS prints.

I cannot over-emphasize the need to flush out any remaining PC filament at the end of the job before letting the machine cool down. I learned the hard way when my last print of the day was PC Blend and I let the machine cool overnight with that filament loaded. Since then I always flush it out with ABS (or whatever, actually) of a contrasting color to be sure that all of it is out.

As for nozzle, the only thing I've used for PC Blend is the standard .04 nozzle, both brass and tungsten. I would agree that a hardened nozzle should be used for the carbon fiber stuff.

If you don't have an enclosure, I would strongly suggest using the draft shield option with PC (blend), which is an option in both PS and Cura.

I always use Layerneer or glue stick with PC Blend filament.

RE: Prusa PCCF usage

With Durabio PC filament I never had to use any enclosure or shields.....printed fine despite heavy stringing on my Ender-3 with a 0.3mm nozzle on a rough PEI surface....maybe too high temperature....but then again you never know what those cheap NTC glass pearl sensors are really measuring (o;

The PCCF fan shroud I printed on my i-Mate S with front door and side panels closed...just left the top cover away....

Now have to wait for the new high temp copper block to arrive for my other printer until I can mount the PCCF fan duct. After that I can hopefully print an extruder holder for my i-Mate S on my Ender-5 Plus (o;

Anyway...this Prusa PCCF filament is just awesome 🙂

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S

RE:

Durabio PC isn't the same kind of PC. It does warp a lot less than the Prusament PC-Blend (is also a lot more UV resistant and scratch resistant but less robust and creep resistent even though it is still quite good in this regard compard to other materials). PCCF however, also does warp a lot less than the PC-Blend because of the CF content.

For PC-Blend without CF an enclosure is absolutely recommended in my opinion and a shield on top of that helps too and even then it is suitable primarily for smaller parts (not much more than ~10 cm I would say) due to warping, even with all of those measures.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE:

Good morning

As I need to print a fan shroud my employer ordered me a roll of Prusa PCCF to test...

Now the big question(s) as I just used PC in the past:

- What is a good printing surface for it? Can I use my rough PEI surfaces or FR4 sheets?

- How do you switch between such a high temperature filament to another one like ASA/PLA?

- Would a M2 0.4mm nozzle do well with PCCF?

- Anything else to watch for?

thanks in advance

richard

I have printed a few rolls of PCCF without any issues. I use the Prusa satin sheet and when the sheet cools the print detaches by itself.

I also use PLA on the machine and to change filament I just load PLA at the operating temp of the PCCF. When the success dialog pops up I say no a few times.

I also use .6mm nozzle and don’t have an enclosure.

just watch out for the wiggle of filament before the print starts as it can get tangled in the print.

i3 Mk3 [aug 2018] upgrade>>> i3MK3/S+[Dec 2023]

RE: Prusa PCCF usage

Is the Prusa satin sheet comparable to those powder coated PEI sheets from Creality?

Though the Prusa one is black whereas the others are golden.

with Micro Swiss Direct Drive, BTT SKR v1.3 and TMC2208<br>Ender-3 with Micro Swiss Direct Drive, E3 mini with TMC2208<br>Qidi i-Mate S