Printing Quality

Hi, I'm a new user with Original Prusa I3 MKS3+ and I have an issue with the printing process.

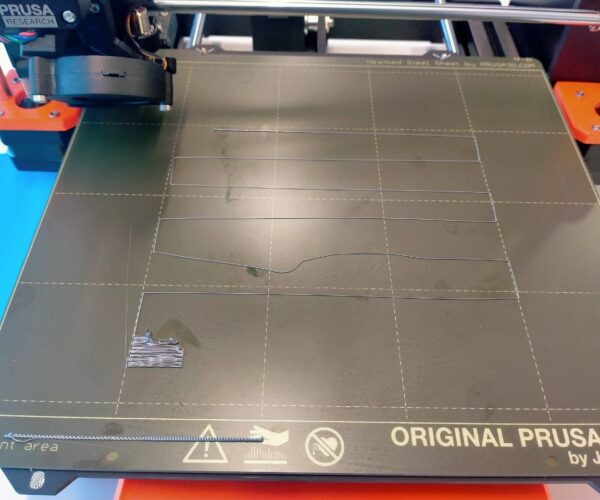

When it starts printing (using PLA), part way through the starting process the print would stick to the extruder and or would break off. And the filament looks inconsistent with its prints. What can I do to improve this?

improve this?

Thank you

Z-offset

It looks like your z-offset is too high. The extrusion lines are not getting squished enough against the sheet and then they don't stick to the sheet. Please run your first layer calibration and post a picture of your results.

Mk3S+,SL1S

Beautiful

Happy printing.

Mk3S+,SL1S

RE: Only partially solved

Hi there @alice-k!

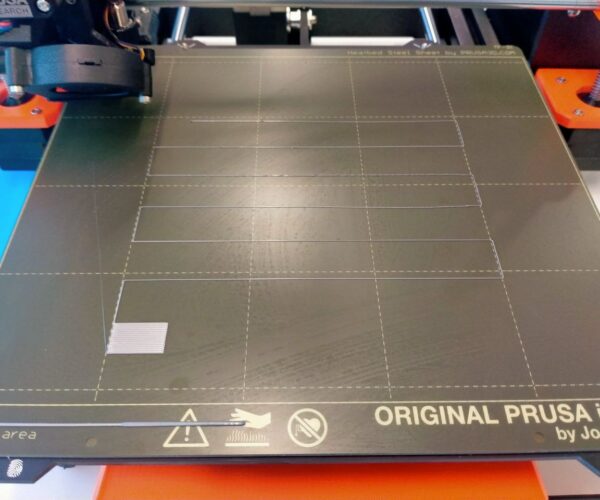

Maybe you succeeded in printing something using your current Z calibration but from your second "fixed" picture it still seems to be way to high (not squished enough) to get the best results and avoid issues. Refer to this to calibrate it properly. Pay special attention to the second picture (the "too low" / "too high" one). One thing to look for is that the printed rectangle should have no visible gaps once detached and it should be as smooth as possible to the touch.

Happy printing!

re

Looking more closely at the pic, I would have to agree with @fortinmike. Clearly much improved but still too high. The corners where the single line turns at right angles are too rounded and should be more squared off and the long lines going the width of the sheet should be straighter and not bumpy.

This is the one calibration that is essential to get right. I suggest that you keep going lower by small increments until it is too low and then go back up.

Mk3S+,SL1S

RE: Thank you

Yes I came across that, and readjusted it quite a few times until I came to a range where it was reasonable smooth at the end.

Now I am printing fairly well without breaking, and I've also used the live Z adjustment and the flow and speed Tunes while it is printing to help adjust for better printing and finish. It was a bit rough around the brim but I think I know how to adjust that too now. And thank you for that link, I was looking at the same image while adjusting it (:

Thank you both so much for your help. Appreciate it!

Another thing.....

.... to check: make sure the filament supply spool turns absolutely freely, with minimum friction that has to be overcome by the extruder, which can lead to underextrusion.

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

Free spool is not the good outcome

On that comment about the spool having to spin absolutely free ... be careful what you ask for. Once you go that route, you need to stop it from spinning and over-running the spool (big knots result). In reality, if you think you need free spooling check your tension screw - it is probably too loose.

I went the free spool path when I got my first MK3S. Then I had to invent ways to keep it from over-running the spool during a print with a lot of extruder movement. On my second MK3S+ I skipped that path and just went with the stock prusa spool holder. It is a work of genius - and has just the right amount of wobble (slows down over-run) and friction. If the tension screw is properly set, you won't see an under extrusion situation.

Agree with Dan. Back when I first got my printer I bought a real cheap roll of filament, the winding on it was really bad. Anyway it had a tangle in it where it just locked up and wouldn't come off the roll at all. By that point my printer was in an enclosure with the stock spool holder mounted on top.

The extruder lifted the entire printer of the deck so it was dangling by the filament. Luckily I was in the room and heard the impending disaster so could hit the reset button. When adjusted those gears grip really well.

Should have mentioned.......

..... that I use a filament "guide" (similar to the line "eyes" on fishing rods) positioned as close as possible to the lateral center of the spool to prevent the situation you describe. This is especially important for full spools, becoming less important as it empties. There's a good design for one on Thingiverse that snaps on to the top frame of the MK3 series, but I don't have the reference number handy at the moment.

Hear ye, Hear ye! Step right up folks and get your Government salvation here! Less than $.002 per word! Amazon.com/dp/B0B8XMMFP4

The wider the better

I use a filament guide too - a wide one that allows the extruder movement a lot of latitude without causing the spool to react. I have found that a small filament guide opening makes spool lash worse. My guidance is make sure your filament guide is as wide as the spool to allow movement.