Practical Filament Tests

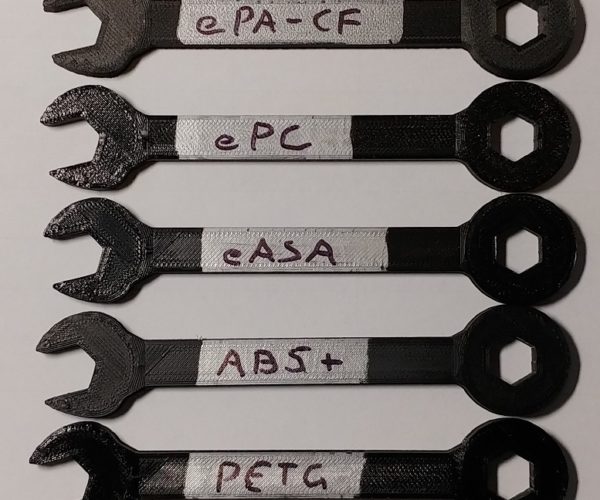

We have all seen various filament tests of hooks picking up tyres, or scientific type impact tests snapping samples prints. We also have access to "data" that tells us all sorts of numbers...... but I just don't know how they relate to everyday use. So, I thought I'd do some Practical Tests on a range of easy to get filament types. In this set of tests, I'm testing a range of eSun's filaments including ePA-GF, ePA-CF, ePC, eASA, ABS+, PETG, and good old PLA+. The data sheets for these claim the following (click on the pictures to see all the details):

1st Practical Test: I've printed a M6 Spanner with both an open and ring end for each filament. Lets see if any of these spanners can tighten a M6 nut correctly. From what I can see, a Class 4.6 ISO Metric Coarse Pitch (lowest spec) has a Recommended Assembly Torque of 3.5Nm and Class 12.9 goes up to 15Nm.

2nd Practical Test: If the spanners survive, I then plan to heat soak them and various temps to see how much they droop. There have been a few posts of issues with Hot End parts that are drooping (eg Pinda). This should give us an idea of what works best for things like our Hot End assemblies or use in cars on a hot day.

3rd Practical Test: Let me know of any other ideas and during weekends I'll give them a go!

I've also attached the 3MF file of the Spanner (it has tight tolerances if anyone wants to join in the fun and also test their filament). I'll post details of my testing method with results tomorrow.

Thanks

Nathan

RE: Practical Filament Tests

I was going to use a Torque Wrench for this test but I don't have one that goes low enough (mine started at 20Nm)... so I MacGyvered it, using a Luggage Scale and just read off the KG at the point of failure. The Spanners are 10cm from centre to centre so approximately 1 KG = 1Nm. Not very scientific but good enough to answer the question. Click on the images to see all the detail.

1st Practical Test - Results for Opened Ended Spanner: All failed to tighten the nut to our target 3.5Nm. They got at best "Finger Tight". That right, you might as well use your fingers that a 3D printer open spanner. They all failed with the Nut slipping in the socket due to the flex. That said the better were held twice as much force than the worst. From worst to best:

- 0.5Nm = ePC

- 0.6Nm = PETG

- 0.8Nm = ABS+

- 0.9Nm = ePA-CF

- 1.1Nm = ePA-GF

- 1.2Nm = PLA+ and eASA

1st Practical Test - Results for Closed Ended Spanner: This is much improved..... but to what I'd call "Great". All did tighten the nut to our target 3.5Nm and some nearly hit the spec for Class 8.8 which is 9Nm. Again there was a reasonable range from worst to best, but it was how the failed that was also interesting. From worst to best:

- 4.5Nm = PETG : Slipped

- 4.5Nm = ABS+ : Fractured

- 4.9Nm = ePC : Slipped

- 5.2Nm = eASA : Fractured

- 6.75Nm = ePA-CF : Slipped

- 6.75Nm = ePA-GF : Slipped

- 7.7Nm = PLA+ : Snapped

Slipped: The wrench handle would bend/flex and eventually the baggage hook would pull out of the open end

Fractured: Both the eASA and ABS+ failed at (see pic)

Snapped: The PLA+ failed catastrophically. I've no idea where the other bit ended up!

Closing Thoughts:

- Don't bother printing Open ended spanners. Might as well use your fingers

- Printed Ring Spanners do work to a point, but it is pretty low point. You will be able to tighten a basic nut at the lowest spec.

- Even though PLA+ had the highest Torque rating, I'd not recommend it as when it fails, bits fly anywhere. You don't want a poke in the eye with a bit of broken PLA+ wrench!

- On a separate test, I did get the ePA-GF to over 8Nm at which point the spanner failed with the nut stripped out the hex part of the ring spanner.

- To get these results the prints were "tight" on the nuts. A more realistic looser fit would yield lower results as it would be easier for the nut to strip out the hex on the plastic spanner.

So the "Winner" is the reinforced Nylon (either ePA-CF or ePA-GF). The flex in these material means that you would end up stop trying to tighten the nut before damaging the spanner yet get a reasonable level of tightness.

RE: Practical Filament Tests

2nd Practical Test - Droop Test Results: I took the spanners, and placed them in the over just supporting their own weight. I slowly ramped up the temperature till each one started to deform and noted down the temp. From worst to best:

- 75c = PLA+

- 100c = PETG

- 120c = ABS+ and eASA

- 140c = ePC

- 200c = ePA-CF and ePA-GF

Setup,

As they Deform,

The end result,

Closing Thoughts: Prusa uses PETG for it's printed parts except the Fan Shroud which is in ABS. From this test, ABS is 20% better getting to 120c before deforming with PETG doing so at 100c. There have been several users complaining about the Pinda Accessory drooping over time. This is not that surprising given the proximity to things like a heated bed that will do over 100c, a hot end hitting in the high 200's and some using a heated print box. The result?

- If you want heat resistant parts (eg for your hot end) then look no further than either of the reinforced nylons (ePA-CF or ePA-GF).

There are some downsides and things worth noting regarding these Nylon Filaments:

- They need to be dry. Not just fresh from the box dry..... but really really dry.

- ePA-CF is a bit easier to print than ePA-GF

- You will need a hardened nozzle

RE: Practical Filament Tests

One thing I noted (and you can see from the photos), the two ePA filaments did not retain their deformed state when cooled. They looked the same as when they were printed and I could see (especially on the ePA-CF) little if any dimensional changes. The both did feel stiffer however, so I took both back to the workbench and did another Spanner test.

- 6.75Nm = ePA-CF : Fractured

- 8.2Nm = ePA-GF : Snapped (like with PLA)

I read that Nylon 12 can be annealed to improve both strength and heat deflection. The recommendation is to try:

- 130-140c for 2 hours

- Turn off oven and let it slowly cool down.

That could be a project for another day as the droop test did not use a slowly cooling down cycle and took the filament all the way to it's melt point.

RE: Practical Filament Tests

Sorry I can't edit the post above (damn forum rules) and it should read.

- 7.8Nm = ePA-CF : Fractured

- 8.2Nm = ePA-GF : Snapped (like with PLA)

RE: Practical Filament Tests

Turned out I had time to try Annealing the ePA-GF and ePA-CF @ 150c for 2 hours then 1hour to cool down then rerunning the test. The results from the ring socket was about the same as above. Interestingly, the open ended results got better (not good however).

- 1.4Nm = ePA-CF

- 1.8Nm = ePA-GF

The higher results for the ePA-GF could be down to the fact that the tolerances are much tighter. This is one of my issues with ePA-GF over ePA-CF. ePA-CF is dimensionally accurate. I find the ePA-GF (with the same print settings) is about 0.5mm bigger in all directions (making gaps and holes smaller). I'm wondering if my ePA-GF is truly dry, so I also measured their weights before and after annealing (and then plan to see if they then absorb moisture over the next week or so). Here is the weight reduction (I can measure down to 0.065 grams)

- 0.5% = ePA-GF

- 0.1% = ePA-CF

Looks like my ePA-GF can do with some more time drying and it will be interesting to see if the fit and finish is any better.

RE: Practical Filament Tests

eSun released a new version of CF reinforced Nylon, this time using PA6 called eSun ePA6-CF (if ePAHT-CF for High Temp?) with much improved specs and a much higher price (about twice the cost of their existing ePA-CF and ePA-GF). I've updated the results of the test but in summary the improvements are in a couple of areas:

- Heat Resistance: This is just the best heat resistant filament I've found yet (that can be printed on the Prusa). It sat in the oven at 240c just fine then as a pushed up the temp it then deformed all at once (well it melted rather than deformed like the others). The specs say the Heat Distortion Temp is 240c which is twice that of ePA-CF and 4 times that of PLA. It's Heat Distortion Temp is just below it's melting temp which is very interesting. The "Continuous use temp" is 150c vs 120c for ePA-CF. Nice.

- Strong: It also was the best at tightening the nut but as it is very very stiff, when it fails, it does so catastrophically (the end snapped clean off, just like the PLA+). I'd still not recommend anyone 3d print spanners.

Summary: I think it will be a great filament for printing heat resistant parts like those for your hot end. It is also great if you want a very very stiff part. Like with the other ePA filaments, to print this well it has to be really really dry. It took me 24hrs @ 70c till the stringing reduced enough that it was worth printing my parts. That said, it is twice as expensive as eSun ePA-CF so unless you really need the extra Heat Resistance and Strength then std ePA-CF is propable a best value for money option.

RE: Practical Filament Tests

I annealed some samples of the ePA6-CF @ 150c for 2 hours then 1hour to cool down and also @ 230c. There was NO deformation of the samples even at 230c but they felt really over dry and brittle so I also then submerged in water for 1hr and left them in atmo for a week. As before, the results from the ring socket was about the same and the open ended results got better, though the 230c open ended spanner sample actually snapped (instead of slipping) so was still much more brittle than originally.

So it looks like the claims of a Heat Distortion temp of 240c is true but such high temps are detrimental to the print. This stuff also has a claimed 150c continuous use temp and Maximum (short term) Use Temp of 180c. It would make a great material for our Hot End parts. Loads of heat tolerance, no drooping, dimensional accurate etc.

RE: Practical Filament Tests

Just wanted to say, thank you for creating these tests and sharing your data. I found this when I was googling the ePA6-CF filament and what people's experiences are with it. I have a few structural prints that will be in proximity to sustained elevated temperatures and need to withstand impacts and this may be a good filament to try out.

RE: Practical Filament Tests

Great work on this, a very useful read.

If you haven't already take a look at this article on nylon vs moisture from an actual plastics industry professional.

I understand the goal isn't making a printed spanner, however a test of nylon spanner stored in a water-filled ziplock for a week as some manufacturers do pre-assembly would perhaps be enlightening.

https://weeklypellet.com/2016/07/22/understanding-nylon-and-moisture/