Not amused...

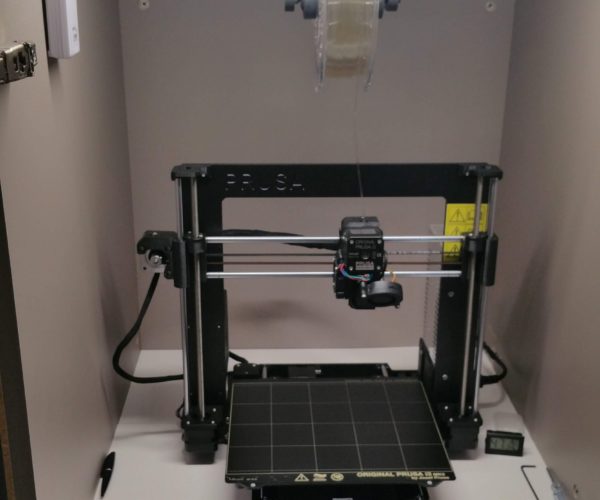

I like to build things (furniture, stuff to my home automation, electronic gizmos etc.) so I decided to get a 3D printer with the intention to spend time on my projects not on the printer itself. After spending days on YouTube and reading forums, the overall opinion was that a Prusa i3 MK3S is the safest bet. So I spent more than twice as much money on the printer as opposed to a cheap Chinese one but I hoped that after assembling it, I will be able to just continue my things.

Assembly went well and the first XYZ Test Cube printed flawlessly. In the next couple of weeks I printed all sorts of stuff with the silver Prusa filament which came with the printer.

Then I decided, that I need a bit more robust housing for an electronic project, preferably ABS.

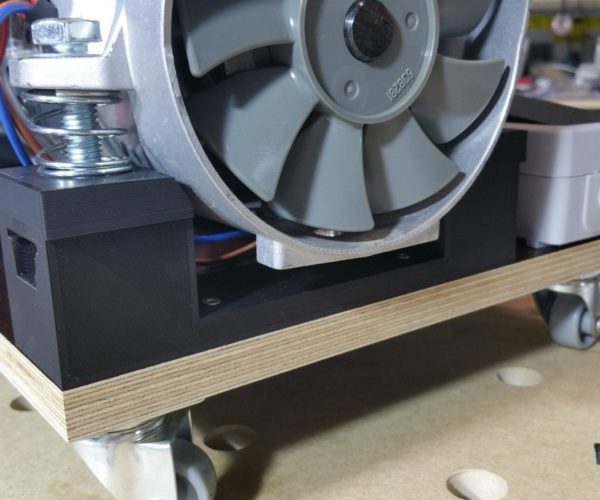

I built a fancy cabinet for the printer as ABS needs constant temperature and opted for the TitanX filament from Form Futura.

The print was flawless... except that I was not able to remove it from the build plate. I freezed it, bent it but it was fused to the PEI sheet in a way that I could only remove it by destroying the sheet and the print. I tried different methods (temp ranges, glue stick, etc.) but it fused all the time. So no ABS and the need for a new build plate.

(A different plate material like glass is a p.i.t.a. due to the calibration before the print.)

Started to print PLA again and for a couple of weeks all seemed okay, except the new build plate was not completely planar regardless of any re-calibrations. Then the printer started to stop printing parts because the extruder was jammed. This started to happen more often until it was not possible to finish any print job anymore.

On to the Net... seems like a common problem with the i3 MK3 and lot's of suggestions but no real solution (definitely not one from Prusa). I changed the heat brake to a Micro Swiss one and replaced half of the hot end with genuine E3D parts + Prusa Tube but I still get filament jams. (I'm using high quality filaments and store them in closed boxes with silica at around 25-30% humidity.)

So after all I spend a hole lot more money and time on the printer and I'm still not able to reliably print my parts not to mention any ABS parts. I'm a constant joke to my friends who are all went the "cheap Chinese printer" way and happily print whatever they want from any sorts of material. (After spending actually less time ironing out their printers problems.)

Did my i3 MK3S printer lived up to it's hype and high price... hell no. Instead of working on my projects, I have to nurse my printer all the time and hope that it actually finishes a print. I could spend even more time on the printer by asking questions and reading trough threads of others, but there is rarely a real solution for these problems just a lot of try this and try that.

Bottom line? Don't believe the hype...

RE: Not amused...

Hi @istvan-k5

I am sorry you got troubles with printing. I have Prusa printer as well and many of us. Going through a starting period can be sometimes strugling but later can be a fun.

We and the forum are here to help each other and share experience.

Generally is known ABS is not an easy material used mostly for smaller parts where its positive attributes (durability, environment resistance) prevail the negatives (difficult to print, adhesivity).

Me personally am carefuly evaluating which material to use for printing in order to get best performance/troubles ratio.

So will be my pleasure and certainly also the others to help you with transition from disappointed to fun status in order to enjoy 3D printing.

Reading your introduction you are technicaly well equipped so the discussion with yourself will be on advanced level.

Would be great if you could describe your partcular troubles in detail to find jointly the best solution. Here in the english forum there is a plenty advanced and skilled users who are capable and willing to help, just if you could be more specific with partcular issues.

We are learning all. I have also destroyed my first PEI sheet just due to the fact I did not read a caution for PETG to put between the model (very tiny one less than 1 cm2 square) and the sheet a thin layer of in package provided glue which makes batter adhesion at the print start and makes easier to grab a ready model from the sheet not destroing it. 😊

If you do not mind let's start with discussion of partcular issues.

btw. Not sure that with the chinees printers anyone can find such a broad and multiligual community ready to help each other. On the other funny side since owning the 3D printer I cannot argue with my wife anything is impossible to construct 😆 .

Regards Zoltan

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Not amused...

[...] I could spend even more time on the printer by asking questions and reading trough threads of others, but there is rarely a real solution for these problems just a lot of try this and try that.

Given this nugget, I'm going to assume you're just here to complain and are not actively seeking assistance from the community. Is that correct?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Not amused...

[...] I could spend even more time on the printer by asking questions and reading trough threads of others, but there is rarely a real solution for these problems just a lot of try this and try that.

Given this nugget, I'm going to assume you're just here to complain and are not actively seeking assistance from the community. Is that correct?

That is my interpretation also. I have 3 MK3S and they all have operated as advertised. One is a clone and even it operates well. I am sure that is not luck or skill.

--------------------

Chuck H

3D Printer Review Blog

RE: Not amused...

I have never heard of ABS sticking too well to any of the sheets. Isn't it generally "I can't get ABS to stay attached!" ??

RE: Not amused...

I have never heard of ABS sticking too well to any of the sheets. Isn't it generally "I can't get ABS to stay attached!" ??

Depends on the age of the sheet and brand of ABS. I have a few rolls of silver MakerBot ABS that stick so right that I can’t get it off a PEI smooth sheet.

--------------------

Chuck H

3D Printer Review Blog

RE: Not amused...

Üdvözlöm Zoltán

sorry for the frustration, I'm most angry on my self. I should have listened to my friends but instead I wanted to be the smart one...

(Please don't underestimate the cheap Chinese printers community. There is a lot of knowledge out there and the printers are working very well.)

Time is a precious thing and it makes me angry that I have to spend so much of it on the printer itself.

I forgot to mention that right at the beginning I had to replace the really cheap linear bearings with Misumi ones because even after polishing the X-Y axis rods to a mirror finish, the movement was still jerky.

Anyway, I spent so much money on the damn thing that I have to stick with it now.

The most important problem I need to resolve is the jamming so I can print PLA reliably again. The other problem (ABS) needs to be addressed later.

Currently I use three different PLA filaments: Prusa Silver, 3D Jake EcoPLA Black and Filamentum Crystal Clear.

As mentioned, all are stored in dry boxes. Jamming is regardless of the filament. I don't understand why the filament sensor doesn't stop the printing when the filament doesn't advances any more. (The clear filament is a challenge but silver and black should be no problem.)

After removing the stuck filament, there is always a little melted blob at the end and there are clear marks of the extruder cogs on the filament. The nozzle is empty.

If I print in the cabinet with the door closed (even with room temperature as low as 14 °C) the jamming happens more often but even with open door it happens all the time. As if the end of the heat break would become too warm.

The hot end fan works perfectly and pushes the air to the fins of the cold end. (Fan Orientation is correct.)

I replaced the heat break with a Micro Swiss TwinClad XT and also built in a new Prusa PTFE tube.

I also replaced the heater block and the E3D V6 Heater cartridge.

This was necessary as the cable to the heater cartridge is so fragile that by disassembly it just breaks.

A side note: the cable routing from the hot end is not very good. The cable needs to be very tightly mounted underneath the print head assembly because otherwise it collides with the bed heater cover in the far left XY position.

This way the heater cartridge cable is bent sharply. The hot/cold cycles do the rest.

Mounting the cable to the side of the head would be much better but there is no space for it in the frame.

Changing the tightness of the extruder cog door screw doesn't seem to affect the jamming frequency.

Jamming happens always after at least an hour of printing. The spool can rotate freely so that should also not be a problem.

Regards István

RE: Not amused...

Istvan - I get the frustration. When you have some experience with the CR10Pro (or whatever import version printer you move to); why not come back here and post your impressions. I'd appreciate some user comparisons between the Prusa and similar models.

RE: Not amused...

Gentlemen,

let us start constructively 😊 and try to help.

Üdvözlöm Istvan,

I am not frustrated at all 😎 I wish we can make you more happy.

can you please let us know a bit more what are the printing details like layer heigth you try to print (jamming obviously happens when printing a super thin layers 0,05mm with high surrounding temperature so the the temperature is increasing along the filament not stopped by heatbreaker) slicer (mainly the print settings whether you use standard or non standard) you use, whether the bondtech gears are skiping over the filament ( it is almost sure in your case when the filament shows extruder cogs marks), so anything you recognize and can describe using your time constraints. Any photos would be great showing the issue.

Regards Zoltan

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Not amused...

Zoltán, I only have some evenings to "play" so please be patient with me. (Some Answers might take some time.)

What I already can tell:

- I'm using Slicer PE latest stable on a Manjaro Linux PC. (Exact version I have to look later at home).

- Firmware on the printer is up to date.

- The latest print was done with standard draft (or is it called speed?) setting (0.3 mm layer height / 0.4 mm nozzle). The only changes were 4 perimeters and Gyroid infill. Filament was Filamentum Crystal Clear. Another print with black EcoPLA with the same settings stopped also roughly 1,5 hour after start.

Temperature in the cabinet was around 16 °C (unheated attic).

Are there any G-Code information you are interested in?

(As I don't save the SlicerPE sessions, I only have the G-Codes to analyze.)

As I wrote, it only happens after a longer printing time, so reproducing the Problem is time (and Filament) consuming.

Regards, István

RE: Not amused...

The Microswiss heat break has an odd configuration, it expands at the nozzle end, opposite the Prusa modified heat break; so probably won't in itself cause jams; but may affect unload for the same reasons. E3D polishes the hot/melt region to reduce friction, MS bores it out. Probably similar print characteristics - but then MS uses titanium, not steel, so the melt zone is probably not as hot, either.

A clear sharp photo of the actual failed print would be informative.

RE: Not amused...

Thanks Tim, the blob is very similar to your photos. I will try to find my "Blobs" in my filament waste bin and make a photo when I'm back home.

I will make a photo as well from the failed piece, although there is not much to see. It just stopped to extrude filament and printed happily in the air.

I changed the heat brake to the MS one because I tought that my jamming problems with the original Prusa print head came because of transferred heat via the heat break. Obviously this was not the case.

In some forum discussions (hier or on reddit) I read that some users blame the stepper motor. The longer I think about it, the more sense would that make. If the extruder motor builds up heat over time it would be transferred to the cogs and make the PLA soft. That would also explain why it happens hours after the start. I ordered some white PLA and as soon as it arrives I will try to print my sensor housing out of that instead of transparent PLA. Then I will measure the extruder stepper motor temperature with a laser thermometer.

RE: Not amused...

Jó reggelt István,

@tim-m30- thanks for joining with valuable input.

István do not worry about our patience, take your time 😉 . Printing 1,5 hours is much less than extreme printing time in comparison to prints lasting more than 10 -18 hours, so printout of 3-4 hours should be without any struggle. How abut the nozzle temperature setting and it´s real temperature like Tim mentioned? At layer height 0,3 mm the gears are trying to push out a lot of filament, so I would a bit suspect the temperature of the nozzle whether it can correctly keep the nozzle (melt) temperature for this amount of filament.

It is also critical during the filament retract moments, if the filament resistance, due to the nozzle low temperature, is to high, filament cannot be pulled back and the blob can increase.

Short article retract vs blobs.

https://all3dp.com/2/3d-printer-retraction-speed-what-does-it-mean/

Let us do the troubleshooting with original Prusa silver filament we all know it´s characteristics.

I am printing PLA and PETG (not ABS) at normal room temperature 20- 23 C° without any problems.

Hear about you soon

Regards Zoltab

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Not amused...

Adding to this, if the motor is the cause, this is what you normally see as a result of the motor heat conducting down the motor shaft: melted plastic below the Bondtech gears.

RE: Not amused...

Adding to this, if the motor is the cause, this is what you normally see as a result of the motor heat conducting down the motor shaft: melted plastic below the Bondtech gears.

How do you prevent this?

--------------------

Chuck H

3D Printer Review Blog

RE: Not amused...

Szép napot Zoltán,

thanks for the interesting article. I copied the filament settings from the normal Prusa PLA (just to respect the different color) so retraction should be the same. Unfortunately I only have a couple of winding Silver Prusa PLA left, certainly not enough for larger prints. I have to test with 3D Jake.

I also use the standard PLA temperature (215 first layer, 210 rest) so it should not be too low.

I will also measure the actual nozzle temperature when I do the test. (I hope my ordered PLA arrives Thursday latest.)

@Tim: this was the case with the original Prusa head. (Melted plastic underneath the gears).

At the end it was so bad that the PTFE tube got completely clogged and I could not remove the melted filament anymore. That was one of the reason why I thought it is the heat break and the reason why I changed it to MS.

With the revised print head I did not had melted plastic underneath the gears, only the blob on the filament.

Let's see what the thermometer will tell us when I do the test...

@Charles: some people stick heatsinks on to the stepper motor and some even fans. Not really what I want to do as it makes the head heavier.

RE: Not amused...

E.g., my motor ran as high as 58c continuously and I never had melted PLA below the gears. If the motor is hotter than that, above 60c, something is causing your motor to run hotter than normal: or you are printing in an enclosure or hot room, or some other factor is raising the motor power requirements and you need to mount a cooling device on the motor.

The powered fan shroud is best, but even heat sinks attached with thermal tape are effective at lowering motor temperature. Neither have been shown to affect print quality. I even added a heat sink 40x40x11 mm just because I didn't like my motor running at 58c, and it is now below 50c. Adding the heatsink has no effect on prints, whatsoever

When you use the IR thermometer, it works well on the painted motor case, but is not effective at measuring the polished metal of the Bondtech gears.

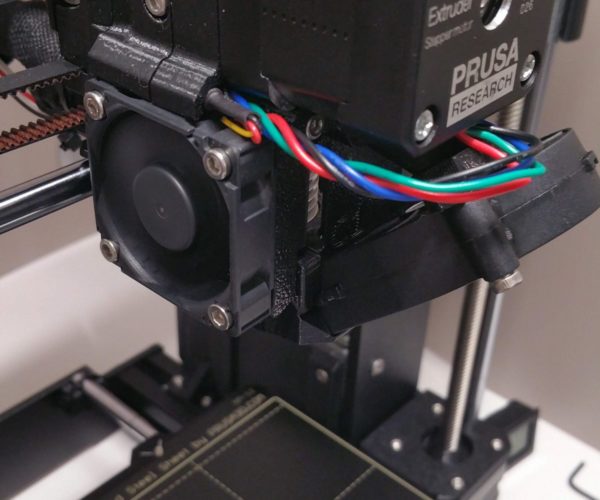

Take a photo of your printer - in place where it is being used - try to include the spool holder. Also snap a close up of the extruder fan - the left side of the extruder.

RE: Not amused...

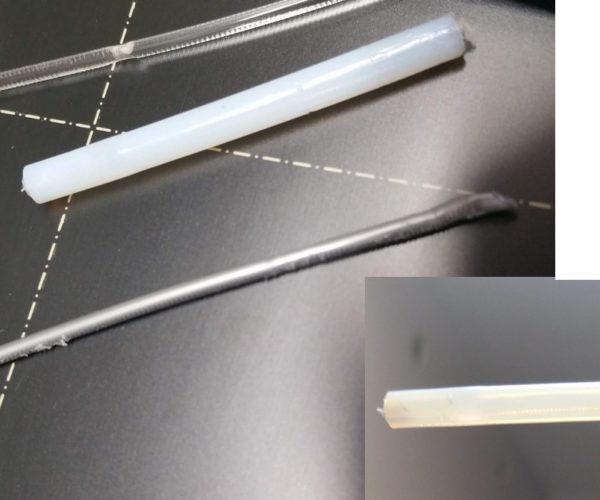

Here are two recent blobs:

The middle one is the old PTFE Tube with the molten in blob at the bottom. In my opinion this was caused by heat creeping up the heat break.

This resulted in a different print result as seen on the following image:

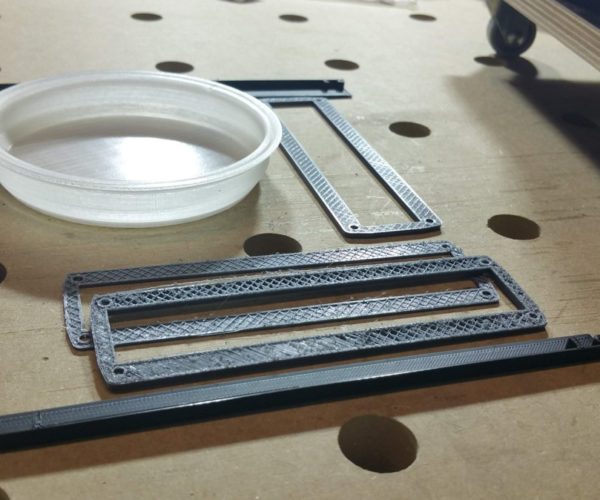

The two lower silver parts were made before I rebuilt the print head. The surface is full of fuzzy filament traces because the there was still some filament dripping out of the nozzle while the head was still printing.

The other silver, black and transparent parts were failed prints after the head rebuild. These show no sign of fuzzy strings because the nozzle was empty as the head was kept on printing. I suppose the clogging was above the PTFE tube this time.

Strangely, some parts (with the same slicer settings as other failed parts) print with no problems, like the two large supports on the following picture:

That's why it is so hard to find why it happens...