RE: NEW E3D REVO hot end

look at CNC kitchens video. He did find out, that the nozzle is actually 5 degs off from the LCD printed temp. This is due to the true design of the revo.

I havent had any issues but its a good thing to note

RE: NEW E3D REVO hot end

The problem is not a stable variation .. it beging to print as 230, then it goes up to 270, then it comes down to 210, 190, then again to 210 .. and it never goes to 230 again.

RE: NEW E3D REVO hot end

I noticed this also when E3D sent me a replacement heater core... That's something I can deal with... but my thought is that it's closer to temp internally in the nozzle... or at least I want to believe that since I cannot get a temp probe inside there... having temps all over the place, as I was experiencing, is not...

RE: NEW E3D REVO hot end

E3D replied and they are sending a new heatercore and they will pick up this one.

Excellent support

RE: NEW E3D REVO hot end

Thanks for all the great tips... I'm still waiting on mine - should be here any day. (Side effect of shipping UK->US->DE->IT )

Anyone tried it on a MK2.5S yet? I'm planning on rebuilding that printer from scratch. Depending on how that goes, I'll decide whether to upgrade my MK3S+ (which right now Just Works(tm) ).

Excited to get two printers up, less excited about spending the hours needed to do so 🙂

RE: NEW E3D REVO hot end

I have upgraded two of my three Mark3S+ and really like it so far. I've upgraded my Mini+ with the Bondtech extruder and the revo hotend at the same time and it's a work-in-progress still.

RE: NEW E3D REVO hot end

I just upgraded my MK3s and have the same issue like Rui Cook. Temps are jumping around like crazy. For a few hours everything worked fine. Then the temps had a few spikes during printing. A few minutes ago the emergency shut off kicked in and now the thermistor is gone for good. Even at room temperature the value isn't stable anymore.

RE: NEW E3D REVO hot end

Contact E3D support.

They are very helpfull and will probably send you a new one.

Mine is already in transit and the old one was picked up today.

RE: NEW E3D REVO hot end

I kind of wish they provided precut PTFE liners, otherwise I'm looking forward to this upgrade. Likely will make the jump when they have more nozzle options.

RE: NEW E3D REVO hot end

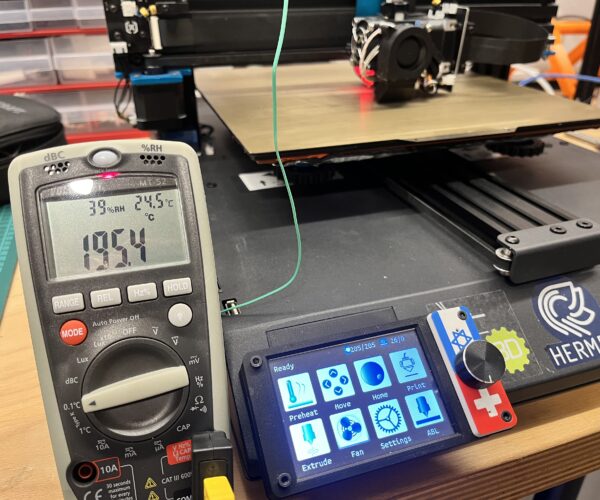

Ok, I have a MK2S with MMU1 with at the original hot end. My 2nd printer is a Artillery Sidewinder X1 / Hemera/Vulcano hotend. I've installed the REVO on the Sidewinder now. Modified the FW to reflect the different thermistor of the REVO. Means from type 1 (general 100kW EPCOS with Volcano) to type 5 (Semtec 104NT-4). Compared temperature reading on the display with a thermocouple inserted into the hotend through a empty hotend (filament removed). I got this idea from CNC's kitchen video on REVO @ Youtube. This is what I got:

204.1°C Thermocouple <> 205°C display of the printer.

Then I turned on the layer fan - and bam - the nozzle temperature dropped the same approx. 10°C like CNC kitchen had.

I printed a ø150mm x 40mm tire in PLA with a 0.6mm REVO nozzle. I have mixed emotions to be honest. I think that there is a fundamental difficulty of the REVO. Thermal conductivity from the heater core to the nozzle is limited and the thermal mass of the nozzle is much lower than the one from E3D V6 Al block. With high feedrates like a 0.6mm nozzle has for example, the temperature of the REVO nozzle itself will drop even further than the measured 10°C since filament melting needs more energy the higher the feedrate becomes. I had to increase the nozzle temperature even further (+20°C) - still my part feels strange if I try to bend it - it sounds like layer between layer cracking sound. Oozing wasn't any issue for me.

Now I print a Benchy at +10°C from what I normally do with PLA (225°C !).

Will see how it turns out.

RE: NEW E3D REVO hot end

Also bought the Revo 6 and I have a lot of issues, under extrusion, extrusion stopping and grinding, contacted E3D, will see if they can help, right now I think I'll be switching back to V6.

RE: NEW E3D REVO hot end

Bumping this thread up...I also got the Revo 6 for my MK2.5S...didn't work for me due to excessive oozing...E3D support indeed was great...they sent me new nozzle and also the heater core but sadly, did not resolve the issues.

Anyone know what should be the resistance values?

RE: NEW E3D REVO hot end

Bumping wont really help, I warned months ago that this would not be easy, frankly it would have been easier to learn how to change a nozzle properly on a V6 hotend,

Good luck y,all lol

welcome to the 3rd world

The Filament Whisperer

RE: NEW E3D REVO hot end

The design is flawed; the quality control poor and changing the nozzle on a v6 is easy when you do it right. I regularly change between .4 and .8 with less drama than on the Revo.

if you really want one handed nozzle changes then get a slice mosquito.

RE: NEW E3D REVO hot end

so I did change back to the original v6 but then I start to have issues with print sticking to my print bed....did all the calibration but its not working anymore...

RE: NEW E3D REVO hot end

I had some drama with the revo, but I think I learnt a bunch which might be of use to you.

I'm running a print farm and upgraded them all. I had problems with two of the heater cores. But having octopi logging temperatures made it very easy to diagnose.

They would under report the temperature while the nozzle was smoking burnt plastic. When looking at octopi you could see intermittent instant temperature drops to 0C

The core issue they had, which still is not fixed is actually the little crimped connections they use for the thermistor. They are not siutable for a flexing cable in constant movement. When signal is lost, temperatures go low and the printer will bake the hotend. It's the curse that the revo is too fast at heating. Most thermal runaway detection won't cut the power before damage is done. Arguably Prusa could change the negative thermal runaway detection to cut the power if the thermistor ever goes open circuit for more than a second. Currently it only kills a print if the temperature 10C lower than target for more than a minute.

Once baked the temperatures will never report correctly again.

They replaced three cores in total over 6 months, since then I have spiced the thermistor connections directly and have not had a single fault since.

They actually have better temperature stability than the V6 even when running 0.8mm nozzles fast.

They work great with the MMU2 especially as after each print it auto ejects filament, so changing a nozzle before starting a print takes less than a minute.

The one bad thing I have spotted is that they run about 8C hotter than they report . This is consistent with CNC kitchens findings. Prints come out fine, but the MMU is very picky about ejection temperatures, I dropped all the stock prusament temperatures down and the ejections worked great.

RE: NEW E3D REVO hot end

Interesting. That's likely what happened to the core that went bad on me. The thermistor cable had a bad crimp--it failed as I was installing. So I clipped the wires, recrimped and got it running. It only worked for about 20 hours of printing, then temperature reporting got really wonky intermittently. The replacement heater didn't have the bad crimps and have been fine so far. My other Revo has been going for 400-ish hours without a hitch.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: NEW E3D REVO hot end

wow...I actually took it out and went back with the old V6 hotend...Would have loved to get it to work.

RE: NEW E3D REVO hot end

... The core issue they had, which still is not fixed is actually the little crimped connections they use for the thermistor. ..

Is the crimped connection at the thermistor end of the thermisto -> connector cable, at the connector end of the thermistor -> connector cable, at the thermistor end of the 'thermistor to the controller' cable or at the controller end of the 'thermistor to the controller' cable?

Also, does anyone happens to know, are these regular Dupont 0.1 locking connectors, and finally, is the 'thermistor to the controller' wire anything special, like a silicone insulated ultra high strand count wire?

As a side note, I bought a preassembled Mk3S+ 18 months ago and have had to replace the bed thermistor cable because it broke internally from flexing, so even the factory wire is subject to fatigue issues. Decided to replace both the thermistor and bed heating cables with ultra high strand count wire.

I need to rebuild the hot-end and was thinking of installing the REVO from here. I don't mind re-crimping and re-wiring it if that is the primary issue, but I'm not sure that is all that is wrong with the REVO.

Thanks for any information that might be offered.

RE: NEW E3D REVO hot end

Just got a Revo 6 here and added it to my MK2.5S - seems to work perfectly out of the box (now/for me 😉