RE: NEW E3D REVO hot end

same problem here.

My right hand is not anymore what they used to be 🙄 after a bad injury.

RE: NEW E3D REVO hot end

@florent-duret

That makes perfect sense, and it is very reasonable at that point to use a tool such as this.

I hold a similar position for work and I often get excited when a project we are working on, works as intended, however I'm the boss and I have to keep everyone in check, (myself included) or things may get sloppy at a critical time.

I'll be watching to see how it works out, I'm also pragmatic.

Regards

Swiss_Cheese

The Filament Whisperer

RE: NEW E3D REVO hot end

same explain thanks a lot

we have to go in educated not just excited.

I couldn't write any better comment.

I'm an engineer in Switzerland and the way I work in my job has a direct influence on my personnal life, thus in my 3D printing hobby.

And I know one of my default is to be "over enthusiast" sometimes.But I'm pragmatic.

Today I'm always scared when I have to change a nozzle on any of my printers (Prusa and Anycubic).

Why?

Because I always fail:

- Lack of precision (from me) when I insert the nozzle in the heater block leads to "glogs" or "leaks", mostly because I NEVER set correctly the space between the nozzle and the heatbreak. I have never been able to "reassemble" a nozzle at the correct position.

This always lead to some leaks, because incorrect distance between nozzle and heatbreak created some spaces in the hotend chamber...- I destroyed/damaged:

- a heater thread when (hot)removing a nozzle leading to full replacement of the hotend package

- the strain gauge on another printer

- the termistor

Yet I'm cautious and careful but I still managed to fail.

(Not totally true because ONCE I managed to replace a 0.4 nozzle by a spare one. Once...)Finally this leads me to never change nozzle (the way other people do): when I really want to change a nozzle, I purchase a full spare hotend just to have a spare part in case of (inevitable) failure from me.

Last month I purchased the copper heatbreak from levendign for the MINI+.

Guess what? I never installed it.So... A solution that would allow the "dumb me" 🙄 to easily change a nozzle on the MINI would solve the issue I meet.

I have preordered the REVO Micro and will fit it in a "dedicated" MINI+. I should receive it in March.Mostly and sincerely, I'm a bit curious to see how this new heater will perform in the MINI+.

Not excited. Curious.

Even if I'm sure I will not change REVO nozzles everyday as I mostly print in 0.4 or 0.6.

RE: NEW E3D REVO hot end

Really looking forward to read first impressions about the REVO micro.

Some people wrote that they swap their nozzles very rarely and thus might not need the possibility to swap nozzles quickly.

But if this is your only printer I think you're wrong. 😬 🙃

I swap my nozzle every few days in a range from 0.25mm to 0.8mm.

A nozzle is a tool you should choose to get the required quality of a print in the shortest possible time.

If you print a functional print that nobody will every see because it's hidden somewhere and the precision doesn't require a small nozzle diameter: Why would you print it with a 0.4mm nozzle?

The simple answer is: because you're too lazy (or afraid to damage something) to swap it.

Or why do you print seomthing like a lettering on a plate with 0.4mm instead of 0.25mm, even that it degrades the quality apparently?

Same answer as above. 😛

Even that I swap my nozzle quite often, sometimes I'm too lazy and think the currently installed nozzle will be good enough for the job.

It's like using the wrong sized screwdriver even if you know that it will kill the screw head a bit. 😉

My guess: A lot people would start swapping nozzles A LOT if they had a system like the REVO micro on their (only) printer.

RE: NEW E3D REVO hot end

A nozzle is a tool you should choose to get the required quality of a print in the shortest possible time.

If you print a functional print that nobody will every see because it's hidden somewhere and the precision doesn't require a small nozzle diameter: Why would you print it with a 0.4mm nozzle?

The simple answer is: because you're too lazy (or afraid to damage something) to swap it.

You, my friend, hit it perfectly. Although it's a little more than fear. I know I can damage stuff.

I got started with this because of Thomas Sanladerer's video. He made a point of using the production version, so I'm pretty confident this will work well. But yes, I'm not touching my new printer until I get the old one back up...

RE: NEW E3D REVO hot end

I'm with you. I'm relatively new (<2 years) printing and have recently ruined my Mini+ hotend by not reinstalling the nozzle properly. It's still in pieces as I'm struggling with getting the heater wire screw out. It might stay in pieces until the revo micro is available.

I'll buy this just for the convenience factor.

v/r

Brian

RE:

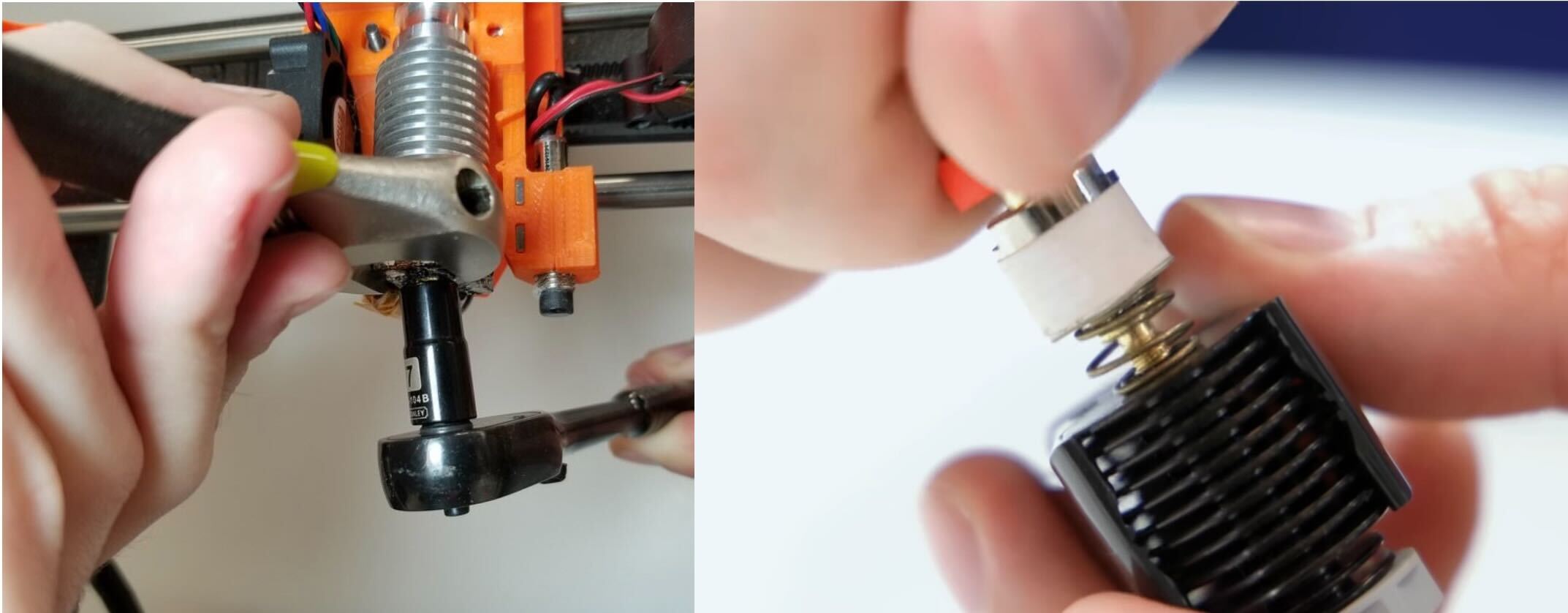

Quick image edit I made to help sell myself on the idea 😀 I mean convenience sells and this isn't perfect but I loathe having to change nozzles.

Here's a video of someone installing it on a prusa printer...

Here's the official instructions https://e3d-online.zendesk.com/hc/en-us/articles/4410028113169-Revo-Six-Prusa-MK3-S-upgrade-guide- which if you buy the kit should have everything you need.

RE: NEW E3D REVO hot end

My last catastrophic failure was actually caused by the heater wire snapping mid print on a big ASA print. The standard V6 design has the wires bent back at quite aggressive angles, which combined with high heat (260+) and long prints in an enclosure can increase the chances of them failing, looking at some of the images, it looks like e3d have addressed this and reduced the angle of exit from the heater block as well as given them extra heat protection and wrapping, this can only be a bonus in my eyes.

RE: NEW E3D REVO hot end

Yes, they have addressed that. Nero did an interview with Sanjay who specifically pointed out the strain reliefs they designed into the Revo heater block.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: NEW E3D REVO hot end

Well, seems like a copy of Raptor hotend idea that is far longer on the market. Anyone to compare those two? Both seem equally cool and one of them is sooner or later arriving in my MK3S+

My opinion may not be right, but regret having so bad and right one too often.My models are things you can't see on any shelve. I create things that don't exist and that should be the…

RE: NEW E3D REVO hot end

I know Nero 3D has both. He likes both and all I recall from his comments is basically the gist of "all hotends these days are good, pick what you like." But he does really like the easy Revo nozzle swap and the fast heat-up time.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE:

Valid points all. I ordered a Revo 6 kit for my Mk3s. I've had nothing but headaches with leaks after changing to a steel nozzle with my stock hot-end. I've had to rebuild the hot-end multiple times to do a cleaning and then put it back on. I have one printer and I can go from PLA to PP to PETG to TPU in one day. I think the constant heating and cooling to different temperatures causes things to become loose (which causes leaks). The way the REVO 6 is made looks like the leaks that occurred for me won't be happening with the Revo 6. Now I'm just waiting for the ObXidian nozzle line to print with steel filled filament and I'll be good.

RE: NEW E3D REVO hot end

My Micro just arrived and it is very nice. The nozzle swaps are going to be stupid easy--it just spins out and spins back in. Easy peasy. I got the full kit, and you can look up the bore of the 0.8mm nozzle to see a nice, smooth path from nozzle all the way to the end of the heatbreak. Said heatbreak extends all the way to the top of the coldend cooling fins. I think you'd have to experience some serious creep to have any leakage in this thing.

No actual use report yet as this one is going in my Voron Trident build, and I have some wiring troubleshooting to do before it's fully up and running.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: NEW E3D REVO hot end

My revo micro arrived yesterday evening, installation was simple and it's all printing flawlessly. The temperatures while printing are so stable its slightly unnerving as I tend to think anything restoring that spot on a result is probably broken but it's been fun testing the capabilities of the different nozzle sizes.

One thing I decided to do which I think has stood me in good stead it's I removed all my custom profiles from prusaslicer and have been using default settings since I figured it's such a big change my previous tweaks might make things worse.

RE: NEW E3D REVO hot end

I'm ordering an E3D REVO for my MK3S+. I will know anxiously wait for other's reported experiences with the REVO before I install mine, which I assume will be months away.

I did just go through a swap in and out of a 0.8mm nozzle and it could definitely be more user friendly. So far this is the first thing I don't particularly love about the MK3S+!

RE: NEW E3D REVO hot end

I always loathed swapping nozzles. Many of my prints would be far quicker and stronger with a .8mm nozzle. But, I would often just use the .4mm nozzle that was installed to avoid breaking wires or dealing with leaks. I just finished installing the Revo in my MK3S+. This has solved one of MY biggest issues/complaints with FDM printers. I didn't get the .8mm nozzle screwed in all the way initially, and when I went to calibrate, it crashed into the bed. It's spring loaded and didn't cause any damage to the nozzle or the steel sheet, and I was off by a good 5mm. I was extremely relieved. So far I'm a happy camper.

RE: NEW E3D REVO hot end

Im pretty tempted to grab the Revo for my new MK3s+, i can't fault this machine at all at stock, prints PETG well, The current nozzle setup is quite a let down, It would be nice to have a quick solution to change heads for different uses.

I can see why people don't like the price of the nozzle heads, but i guess people are use to the market being flooded with cheap nozzles.

I have no issues paying for a high quality product, i just hope that they use the higher margins to improve and develop their products.

hopefully we see a hardened nozzle option in the near future, I've got a few projects its that need some CF in the near future

RE: NEW E3D REVO hot end

Im pretty tempted to grab the Revo for my new MK3s+, i can't fault this machine at all at stock, prints PETG well, The current nozzle setup is quite a let down, It would be nice to have a quick solution to change heads for different uses.

I can see why people don't like the price of the nozzle heads, but i guess people are use to the market being flooded with cheap nozzles.

I have no issues paying for a high quality product, i just hope that they use the higher margins to improve and develop their products.

hopefully we see a hardened nozzle option in the near future, I've got a few projects its that need some CF in the near future

I don't believe you have a full grasp of what your talking about, the E3d stock hotend is a high quality product, it just turns out that not everyone can handle the mechanics of maintaining one. kind of like people that cant work on their own cars, so they have to pay a premium to have them fixed, if your proficient with nozzle changes you can change them repeatedly in about 2 min (realistically) without father issue.

The quality of the nozzles for the V6 hotend, if you buying genuine E3d nozzles is impeccable, as well you have many more nozzle types and options available to you at a lesser cost, the REVO is for people that have problems changing nozzles and at least currently only print non abrasive materials, your paying more because you can't change a nozzle without causing yourself problems, not because it's a higher quality, you should be clear on this.

Do your research, learn what you need to know and get good at it, don't be sheep.

Swiss_Cheese

The Filament Whisperer

RE:

Im pretty tempted to grab the Revo for my new MK3s+, i can't fault this machine at all at stock, prints PETG well, The current nozzle setup is quite a let down, It would be nice to have a quick solution to change heads for different uses.

I can see why people don't like the price of the nozzle heads, but i guess people are use to the market being flooded with cheap nozzles.

I have no issues paying for a high quality product, i just hope that they use the higher margins to improve and develop their products.

hopefully we see a hardened nozzle option in the near future, I've got a few projects its that need some CF in the near future

I don't believe you have a full grasp of what your talking about, the E3d stock hotend is a high quality product, it just turns out that not everyone can handle the mechanics of maintaining one. kind of like people that cant work on their own cars, so they have to pay a premium to have them fixed, if your proficient with nozzle changes you can change them repeatedly in about 2 min (realistically) without father issue.

The quality of the nozzles for the V6 hotend, if you buying genuine E3d nozzles is impeccable, as well you have many more nozzle types and options available to you at a lesser cost, the REVO is for people that have problems changing nozzles and at least currently only print non abrasive materials, your paying more because you can't change a nozzle without causing yourself problems, not because it's a higher quality, you should be clear on this.

Do your research, learn what you need to know and get good at it, don't be sheep.

Swiss_Cheese

I’m not being a sheep, I just believe things can be improved, i didn’t say the hot end was a bad product, it just needs refinement, these are still rudimentary machine in respect to machinery that has been available in other disciplines

as for nozzles, I was implying that the problem is the current way of fitting them, it just isn’t a great solution in my view, and using a cheap nozzle just cause issues that will cause issues for some people, even more so, if they aren’t able to troubleshoot well

My workshop is full of Festool and felder machinery, time is money, so quick and easy tool changes are very worthwhile without any issues.

I cut my teeth doing my trades using old school machines, so I now how to fix and adjust them, but I don’t miss them one bit as they have moved forward with a lot of development, with quick repeatable tooling changes.

I personally think quick change heads are the future, you have to remember from a business point of view, you don’t want your consumers getting frustrated, you have to make it easier and more reliable for all.

just from reading a lot of posts, a lot of people are scared of changing nozzles, due to issues, the market needs to work on this.

by the way, I change my own oil, I’ve even rebuild engine for myself and I know how to use a torque wrench.

The new revo no wear nozzle that is expected later this year sound promising, looking forwards to seeing the reviews.

RE: NEW E3D REVO hot end

not because it's a higher quality

You are joking, right? The Technology of the Revo heater is miles ahead of all current hotends on the market.

I would now buy a V6 Hotend only, if i would never change nozzles.

However, i am a bit worried that the Revo nozzles now are much more expensive than E3D promised initially.