I just had a wild idea for a recycling apparatus.

I just had a wild idea for a recycling apparatus. Why not melt the plastic flat, then chop up the flat plate to get a consistent pellet size?

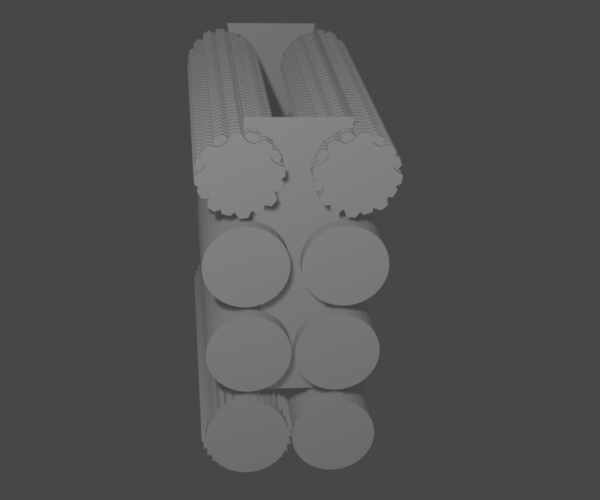

Maybe a series of heated rollers. Start with knurled rollers, maybe even slightly spiked, like a meat tenderizer, to get a good grip on the scrap, and progress to smooth rollers, then finally (probably unheated) rollers with embedded blade edges, like an agricultural stalk cutter, to chop the extruded plate into even-width ribbons, (which would exit "sideways" from the chopper).

The ribbons can then be fed through a second, unheated, chopper to cut them further into little rectangular prisms of plastic. This second chopper would be similar to the last chopper, but would not use heated rollers to deform the plastic into a sheet first. It might benefit from rubber rollers to get a grip on the ribbons and feed them into the chopper, or you could just use gravity. You'd probably need some form of restrictor grate to prevent too many ribbons from feeding into the second chopper at once, so you don't end up welding the ribbon pieces together by pressure, or jamming the chopper.

I can think of three ways to heat the rollers. Put heating elements down the middle of them, flood them with hot oil, or place an inductive heating element behind the set of rollers on either side. Inductive heating elements seem easiest, as you'd theoretically only need two, one per side, and you wouldn't have to deal with leaks, or with the headaches of putting a heating element in a rotating part.

Keeping trash out from behind the rollers might be a bit of a challenge. There would probably need to be strips of something, probably glass or ceramic since it wouldn't get heated up by an inductive element, or melted in the heat, between the roller pairs on the working side of the rollers on either side. Imagine taking a rectangular funnel and cutting matching slots out of either sloped side, leaving the parallel sides mostly alone. Into each of these paired slots, one on either side of the funnel, a pair of metal rollers protrudes into the funnel. The material that remains serves to guide the plastic into lower and lower, more restrictive, roller pairs. A crescent of material IS cut out from both of the parallel sides for each slot, as it'd be best for the rollers to be slightly longer than the sides of the funnel, rather than shorter. The rollers protrude to some point short of their axii. How far they protrude is up for debate; more and they grip the plastic better, but less and less trash gets into the space behind the rollers. The top, knurled, rollers probably need to protrude more deeply into the funnel volume than do the smooth finish rollers toward the bottom.

I said that the sides should probably be of a glass-like material, for a combination of strength and to not get heated up by the inductive elements, but now that I think about it, it would probably be better if the sides were as hot as an electric skillet, so metal, especially steel, is very much on the table, at least for some sections, (not close to the chop rollers). T-section would be best, but a pair of angle-iron extrusions, with maybe a skinning of a thinner material over the resulting wide face, would work quite well and likely be easier to source. The section could then be supported from the protruding spine.

There'd probably still need to be some way of cleaning out the little bits that made it behind the rollers anyway, but this just means you need to be able to take the sides off, and you need to be able to do that for service anyway.

It should be possible to drive all the rollers off of a single motor. A standard 'V' belt would provide a compromise between keeping the rollers turning at the same speed, or perhaps a fixed ratio, based upon how constricted the funnel is at that point, (although this would require gearing the rollers), and allowing rollers to "slip" if something got wedged. The belt needs to engage the pulleys of each roller solidly, so while I don't think a toothed belt is ideal, idler pulleys between the roller pulleys, or serpenining the belt between both sides, (although now we're talking about a flat belt), would help ensure that the middle rollers engaged with the same tension as the upper and lower pairs of rollers.

The largest cost, besides a motor with enough torque to do the job, would probably be creating the rollers. For the middle, finish, rollers, something as simple as smooth steel pipe, with bearings pressed into both ends and a pulley secured to one end with a set screw.

The chopper rollers need to have metal edges secured in them, and ideally replaceable as they'll wear down. The obvious answer is to use a thicker-walled pipe, and cut grooves around its face, then secure the blades from either end with bands, but this may not be cheap enough.

Since this roller doesn't need to be heated, it may be possible to produce it from another material, such as wood, or maybe printed plastic, (although it'll be a long, straight, extrusion that needs to be of consistent dimensions, and needs to resist a fair amount of pressure along its length). It might also be possible to add additional support to this chopper in the center, using a gnurled wheel with the indentations lining up with the blades, so the surface of the wheel only puts pressure on the roller in between the blades. The wheel should be rubber, and replacable, as the blades will, over time, whittle at the edges of the indentations, and you don't want to dull the middle of the chopper blades faster than elsewhere. There is no limit to how many support wheels can be added in this manner. The blades should be ground square, or even with an acute angle, but probably don't need to be hardened, and I think you could make them out of thin, flat, bar stock.

Edit to say. The chopper rollers don't need blades on both sides. One side can cut against the other, and this would probably be better.

The other rollers can be supported similarly, but since at least some of them will be heated, the support wheels for those other rollers need to be of a heat-tolerant material. Wood comes to mind, considering the temperatures involved. It would wear the rollers minimally, while not reaching a temperature that would be detrimental to it. They would not need to be highly dimensionally accurate and could probably be produced, with a steady hand, by chucking up a rough wooden wheel in a hand drill and carving it down with sandpaper. Springs to keep them pressed against the rollers under tension would make up for any variation in radius from wheel to wheel. The easiest way to fashion these springs would be to use leaf springs secured to the frame itself and pressing on a swinging arm attached to the axle of the support wheel. This swinging arm could possibly be manufactured from a wide, short, "U" bolt, if the need for tension isn't too high, fed through a bearing in the wooden wheel on one end, threaded through a pivot on the frame, and with a leaf spring, bolted to opposite side of the frame from the pivot, threaded through the U-bolt, bearing directly against the wheel-end of the U-bolt, to provide tension toward the roller.

The knurled rollers could be fashioned by any of a number of methods. I'm leaning toward building the things up from knurled nuts, or even threaded gears, fitted down the length of a threaded pipe or rod.

The deeper the funnel, the more roller pairs, and more separate constrictions, the more even the resulting plate will be prior to chopping, and consequently the more even the resulting pellets will be after chopping. The ideal would be to be able to remove the chopping rollers and use the thing to produce recycled plastic sheet of a consistent thickness.

This would replace using a blender or repurposed paper shredder to produce "pellets" to feed into the extruder. It should be capable of producing a more consistent size than what either of those two methods are known for. It would not replace the filament extruder. It might also sit between a shredder or blender and an extruder in the production chain, and this would allow for a smaller apparatus, owing to a more regular size of input, (it would have to be big enough to ingest, AND GRIND UP something as big as a Benchy, if all models were reduced to consistently smaller, if irregularly sized, pieces).

RE: I just had a wild idea for a recycling apparatus.

Sounds interesting. Are you willing to sketch up a visual reference of what this might look like?