Glue for printbed?

May be a simple question, but a tube of "Glue for Printbed" came in my kit. What is is used for?

Bob

RE: Glue for printbed?

A couple of things. But NOT for PLA. It also depends on the sheet you have. PEI or Powder Coated.

ABS is notorious for not sticking well and needs a mechanism to hold it to sheets. GluStick can help; as does ABS Juice. Nylon, and some other materials, same. It can also be used as a release agent for materials that stick too well: PETG for example on PEI is well known for destroying sheets. GluStick reduces adhesion (but Windex is better).

Bottom line: read up on the different materials and ways to print them well.

RE: Glue for printbed?

My glue stick is still in the box it came in. Along with the acupuncture needle. Needle I might need someday...

RE: Glue for printbed?

That is so interesting. It works to help adhere and as a release agent too! My PETG is sticking so firmly to the PEI sheet that i have trouble getting it off. I will try it. Thank you for your guidance. This is one amazing machine!

RE: Glue for printbed?

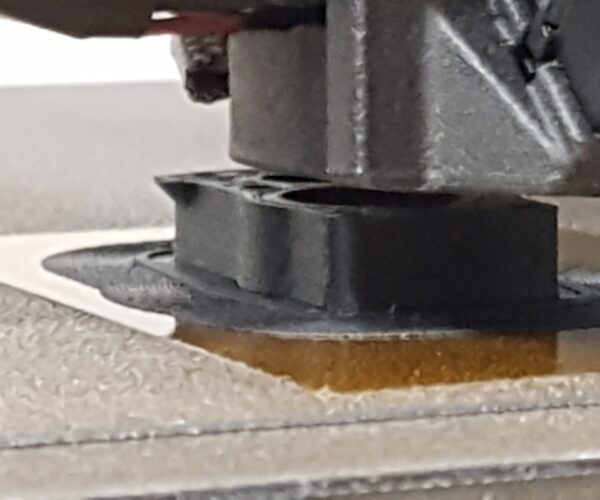

On the smooth sheet, there is an initial line drawn along the front of the sheet. That line was almost impossible to remove, so I used a sharp knife which scratched the plate a bit, but not where it mattered. After these posts, I applied "Kores" to the area. It worked great. Subsequent wiping with isopropanol apparently spread it all over the surface to a wonderful effect. My PETG now pops off effortlessly! Thank you all for the insight.

RE: Glue for printbed?

Never use steel on the print sheets. Get a plastic - something. You really don't want to damage your sheets.

Thingiverse has a scraper you can print. My current favorite are the plastic razor blades you can get on Amazon.

RE: Glue for printbed?

initial line drawn along the front of the sheet. That line was almost impossible to remove

That is the reason my custom start g-code deposits intro line from a slightly elevated Z. The intro line comes off a lot easier.

M83 ; extruder relative mode

G28 W ; kuo MUST FIRST home all without mesh bed level or else risk nozzle crash!

G0 X70 Y70 Z0.2 F2000; PINDA warms faster near bed

M140 S[first_layer_bed_temperature] ; set bed temp

M104 S160 ; preheat extruder to no ooze temp to help warm PINDA

M190 S[first_layer_bed_temperature] ; wait for bed temp

M109 S160 ; wait for extruder temp

M860 S36 ; wait for PINDA temp. For most stable PINDA temp during mesh, check your actual PINDA temp at end of mesh call and enter a temp here 1-2 deg below that value.

M104 S100 ; drop extruder to lower temp to minimize PINDA temp rise during mesh

G80 N7 R3 ; mesh bed leveling

G1 Y-3.0 F1000.0 ; go outside print area

G92 E0.0

G1 Z3 ; raise head safely clear of bed before heating extruder

M104 S[first_layer_temperature] ; we heat extruder AFTER mesh to minimize ooze

M109 S[first_layer_temperature] ; wait for extruder temp

;M900 K0.075 ;set LA 15 kfactor PETG ;uncomment to use LA 15

G1 Z0.7 ; kuo move slightly above bed for easy clean intro line

G1 X60.0 E9.0 F1000.0 ; intro line

G1 X100.0 E12.5 F1000.0 ; intro line

G1 E-0.8 F2100; bobstro anti-stringing retract and wipe

G1 X99.0 E0 F1000.0 ; -1mm intro line @ 0.00

G1 X110.0 E0 F1000.0 ; +10mm intro line @ 0.00

G1 Z0 ;kuo lower head back to normal Z after intro line

G92 E0.0

M221 S{if layer_height==0.05}100{else}95{endif}

RE: Glue for printbed?

Any ways back to PVA glue.

There are two scenarios I always use PVA glue. (Elmers Ultra here)

1. Flex filaments - these stick far too aggressively otherwise. Wetting print plate after print job dissolves glue and allows easy parts removal.

2. Polycarbonate - usually won't stick well enough without a layer of PVA glue and a brim.

My technique is to spread one two layers at right angles to each other. Spray with water and work with a paper towel to dissolve glue to a syrupy consistency and spread evenly. Dry at 100C for 5 minutes. Between print jobs, a localized touch up with some more glue and repeat water spread to renew glue layer. PVA is interesting in that it dissolved with either IPA or water. It's simply easier to spread a uniform thin layer with water. However, you must dry the plate before use.

My Tekking textured PEI plates are perfect for PETG without glue. PETG sticks perfectly during print and parts practically fall off when plate cools. No need for glue on a Tekkking as release agent, but other PEI plates (e.g., prusa's flat PEI) may need PVA to allow release.

RE: Glue for printbed?

My problem is that the PLA-prints doesn't stick to the plate. Print starts OK, but after some layers, maybe 15-20, the parts are thrown out.

May I use some kind of glue?

RE: Glue for printbed?

Glue stick is needed for big flat parts, because these can curl up, also for pla.

Keep bed clean, very clean is needed. After this if it still not sticks use glue stick.

Also if a part only has a small footprint on the bed , then use glue stick.

RE: Glue for printbed?

Glustik is not as effective at holding a part down as a clean PEI sheet. If a gluestik helps PLA adhere on a smooth PEI sheet, then the PEI sheet is not clean: instead it is contaminated with oils and print residues and needs to be cleaned with soap and water.

RE: Glue for printbed?

I never need a gluesick except with certain filaments.

--------------------

Chuck H

3D Printer Review Blog

RE: Glue for printbed?

Ideally use a heat resistant glue like the Loctite GO2 Gel Super Glue . I took it more than once for different purposes until I let it down.

RE: Glue for printbed?

you need this e.g. for flex printing on smooth PEI sheet, otherwise sticks too strong and you are unable to remove from sheet (it is a separating film).

Better solution however is to use smooth and texture sheet and flip between the two dependent on material you print.

Best, Matt

RE: Glue for printbed?

I prefer kapton for special materials (a CarbonPEEK print - 140 degrees bedtemp.):

https://www.3dprintingmedia.network/new-3d-printing-kapton/

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Glue for printbed?

The places where I most seem to need glue stick is with the first layer with very small supports where the ends of the first layer seem to gently curl upward and detatch. When I do a print that needs these supports I'll put a thin layer of glue right in the area where those supports are going to hit the print bed.

RE: Glue for printbed?

But really, as far as glue is concerned, you have to try to make it stable. It's kind of the most important thing. If you don't know much about glue, you should read about best heat resistant glue https://gluefaq.com/best-heat-resistant-glue/ . It's just in this article that you can find the best material to choose from. In addition, the pros and cons of this or that glue are described. Because, it may happen that specifically under your material may not fit the one I suggested earlier. So it is better to read the expert opinion and then make up your own. Good luck!