RE: Drying filament - temperature precision

Here's an interesting example of what people have to do to make wet PLA:

https://3dprinterchat.com/pla-filament-moisture-study/

The filaments were first pelletized into uniform pieces and exposed to distilled water vapour for 14 days at 130 degree Celsius. Then they were tested for moisture content. Initially black and white filaments from first manufacturer were tested and it was found that moisture content kept increasing in both filaments up to 140 – 150 hours. After 150 hours, the material attained its saturation.

That's 150 hours at 130c and 100% RH to make wet PLA... not many of us have that sort of environment.

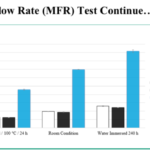

The article goes on to imply yellow filament absorbs more water than blue, and blue more than black or white. And yellow and blue filament flows more readily than other colors, regardless of moisture content: and the weird part, though they don't clarify the point: the delta between colors is larger than the delta between wet and dry.

RE: Drying filament - temperature precision

I think you're underestimating the raw potential of a shipping company that simply doesn't give a damn about the stuff rolling around in their warehouse and trucks during a hot and humid southern heat wave. We had the example of someone posting pics of a "defective" roll of Prusament exhibiting the same hex pattern as on the spool. I wouldn't be surprised if filament is regularly exposed to high temps and humidity during shipping.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

High temps and deformation is expected: but in a shipping baggy they normally com in, humidity during transit shouldn't be an issue. And certainly no where near 130c at 100% RH. btw: That article moves on to say they had to immerse the filament for days to get it really wet enough to do their flow tests. So unless the container goes down with the ship and is recovered years later washed up on a Washington beach, and then someone tries to print with it... lol

I recently dried some no-name wood filament that was rather stringy out of the bag. A year later, it was slightly less stringy after spending a day at 50c ~3% RH. I doubt I'd have noticed the difference except I intentionally tried drying the 'worst' filament I own.

ps: the wood in the filament probably had moisture in it when they were making the filament, and the PLA surrounding the fibers keeps the wood wet even though drying in a dehydrator.

RE: Drying filament - temperature precision

High temps and deformation is expected: but in a shipping baggy they normally com in, humidity during transit shouldn't be an issue.

That is true. It shouldn't be an issue. Then again, my textured sheet should be awesome for use with PLA...

And certainly no where near 130c at 100% RH.

That seems to call their testing methodology more into question than categorically rule out moisture absorption of PLA. A number of sources, both scholarly and practical, certainly indicate that PLA can be impacted by moisture:

More importantly than any scholarly pronouncements (IMO), I've had personal experience with PLA that improved significantly after drying. Not all PLAs are the same, after all. The elusive NASA study apparently noted differences in UFP emissions with dried versus "undry" PLA as well. So moisture does something to PLA.

btw: That article moves on to say they had to immerse the filament for days to get it really wet enough to do their flow tests. So unless the container goes down with the ship and is recovered years later washed up on a Washington beach, and then someone tries to print with it... lol

I like the conclusion in the 3dprinterchat link:

Hence it is clear that it is necessary to manage the storage conditions of PLA filaments. Too tropical and humid countries require better supply chain conditions than drier lands.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

I printed a very nice piece with Polysmooth. About a week later I printed the same piece, only to see a lot of stringing and much less evenness in translucency among layers.

In the last 3 years I've never dried my PLA. Some brands are getting brittle over time but I couldn't identify any moisture issues on my PLA so far. If you see a difference already after one week then you must live in a tropical zone during rain season.

Most likely causing other factors like ambient temperature, printing speed, different objects different results. For example the nice and shine Polyalchemy Elixir PLA need to be printed at the right temperature. Keep in mind that if you have 20mm/s area and next to it 200mm/s area then the actual extruded temperature will be different. Such a things you can see on the print. The one will be shiny the other rather dull.

So if you print PLA only, then I wouldn't invest in any kind of dehydrator. For Nylon, PC, ABS on the other hand you need one. And you can go as cheap as you can as long as it can hold +/- ~5C. You're not doing any scientific research/experiment. If it bounce a lot, just keep the filament longer in there because you can assume it was colder (more humid) inside as set.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Drying filament - temperature precision

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

@bobstro

How do you store your filament? I put mine in a sealed box (without silicone) and that works fine for me.

I would understand if the OP has used old filament. But we are talking about one week time difference! My bet goes on other factors but not old/wet filament.

A also agree that you can refresh your old filament by bringing it to the transition point and leave it there for couple(>12) hours . But this was not the initial question.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Drying filament - temperature precision

How do you store your filament? I put mine in a sealed box (without silicone) and that works fine for me.

For the most part, I store it in whatever bag the manufacturer provides if resuable, and otherwise use a 2 gallon Ziploc freezer bag. I toss in a couple of packets of recharged desiccant. I notice that the desiccant changes color (blue to pink for this stuff) indicating there is moisture ingress. The affected spool was older (perhaps 9-12 months) so it could be a variety of factors, but the pre-print "toasting" got it to behave well enough to burn off the remainder of the spool.

I would understand if the OP has used old filament. But we are talking about one week time difference! My bet goes on other factors but not old/wet filament.

The variable is how long the stuff sat on a shelf, and what conditions it was stored and transported in. That case with the deformed Prusament really drove the point home for me. (Note: A major softdrink has a factory producing diet drinks in Phoenix, AZ. They routinely leave pallets of the stuff sitting out in 120F+ heat for days. If your drink tastes funny, it's probably not your refrigerator!)

No doubt PLA formulations vary as well. I suspect this is going to be another one of those "inexact science" topics where individual results can vary widely, even with the same equipment, materials and settings. I generally haven't had issues with PLA but this was a hell of a muggy spell. Not a smoking gun by any means, but I was glad to not have to toss the filament.

A also agree that you can refresh your old filament by bringing it to the transition point and leave it there for couple(>12) hours . But this was not the initial question.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

I printed a very nice piece with Polysmooth.

Lest it be lost in the discussion, Polysmooth is PVB, not PLA. From the Matterhacker's page:

Recommended to dry at 60˚C for at least 12 hours before printing, this material is pretty hygroscopic

The manufacturer's page recommends the same.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

Thanks for pointing that out. Most likely it's like Nylon. One week is enough to make a huge difference in print quality.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Drying filament - temperature precision

Thanks for pointing that out. Most likely it's like Nylon. One week is enough to make a huge difference in print quality.

Polyvinyl Butyral according to the all-knowing Alexa.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

I would like to help with the debate regarding PLA and drying, but I simply don't have good data. Of the roughly 80 spools I have in stock, only two are PLA. PETG and Polycarbonate are the bulk of materials here. Those, there is no debate whether drying is beneficial.

RE: Drying filament - temperature precision

Just completed my somewhat scientific test of drying PLA filament.

Two samples of PLA filament: same spool source and approximately equal in weight and surface area:

17.987 (1) and 18.081 (2) grams. Calibrated against a 20.000 gram reference (19.996 grams), and samples were weighed five times and the average taken. Scale used has a claimed accuracy of 5 counts.

Samples were placed into a sealed 2L chamber with 70 grams (2.5 ounces) of hot water, with room temperature air at (range of 21.5c to 23.5c). Humidity reached 80% in a few minutes, and was at condensing saturation within an hour.

Sealed chamber was left unopened for more than 30 days to achieve equilibrium in the plastic.

note: I used this method because the official equilibrium method requires a control humidify of 50 %, and I don't have the equipment to do that; and the official saturation method would melt the plastic (100% 100c steam environment). Also, PLA is not known for absorption, and wetting the plastic no longer than 24 hours as the official test methods describe seems insufficient for simulating what we do as printers.

After 30 days, I removed the samples and weighed them: 17.987 grams (1) and 18.081 grams (2).

Placed one sample (1) in a vacuum chamber set to 29.95 mmHg at 15.5c (garage).

Placed one sample (2) in a food dehydrator set to 122f.

After 10 minutes I removed sample (1) and weighed it: 17.968 grams. Sample was returned to vacuum.

I was checking to see if a short vacuum was effective at rapidly removing moisture, as some claims have suggested.

After 4 hours I removed sample (2) and weighed it: 17.972 grams. Sample was returned to dehydrator.

I was checking for time efficiency.

After 8 hours I removed both samples and weighed them: 17.899 (1) and 17.952 (2) grams. I then placed sample (1) into the dehydrator and sample (2) into the vacuum jar.

After an additional 8 hours, I I removed both samples and weighed them: 17.858 (1) and 17.952 (2) grams.

Here is the table of data and results.

From the data I conclude:

0) The PLA samples absorbed at least 0.7% of their weight in H20 in 30 days when kept in a high humidity environment.

1) The heat of a dehydrator is the best drying method, and 4 hours is insufficient to fully dry PLA. At least 8 hours is recommended.

2) Drying by vacuum is not sufficient, and is much less effective than even 4 hours in a dehydrator.

Other notes:

I am curious if there is more moisture in the PLA. I may do a destructive test at 100c to remove as much moisture as reasonable possible without also boiling off other volatiles in the plastic. I will report any results back here.

Samples were designed to test both coiled and printed filament, and consisted of about 10 grams of coiled material and 10 grams of printed material.

Swapping samples provided a fair test to compare final weight changes and moisture removal: heat drying the already vacuum dried sample (1) resulted in a final weight reduction quite close to the other sample (2), 0.717 % vs 0.713%. It is curious that placing the heat dried sample into a vacuum had no measurable effect, and makes a strong case a vacuum drier is not nearly as effective as heated drying, and also hints that 0.71% represents 100% of the water load absorbed.

RE: Drying filament - temperature precision

Glad I didn't go for a vacuum setup! Results with my PrintDry dehydrator-style drying have been consistently good.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

Thanks! Tim. Nicely done.

RE: Drying filament - temperature precision

Placed the samples in a convection oven at about 100c for an hour, then into the dryer at 74c (165f) for another 8 hours. Final weights indicate they lost 0.75% moisture by weight. Less than 0.05% drop from the 8 hour bake, and requiring destructive temperatures.

It looks like 4 hours will remove a significant amount of moisture from PLA, and 8 hours is all that is really needed to dry it to a reasonable limit. Whether this holds true for all PLA, I can't say.

Next on my list is PETG and ABS. I may even include samples of PLA2. And I'll forego any vacuum tests, seems a wasted effort now.

RE: Drying filament - temperature precision

While I'm still bagging filament with a recharged desiccant packet, I'm firmly in the "when in doubt, bake it out" camp now. Freshly cooked filament works reliably, and the bonus of reduced UFP production seals the deal. I don't worry too much about PLA, but if things start to go wonky with stringing or quality, I do give it a toasting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

But I am back to the simple fact that after 30 days in 100% condensing humidity the PLA I used collected a whopping 0.75% moisture by weight. I'll restate that other labs doing tests had to immerse PLA in 100c steam for days to get the PLA to absorb moisture, so my test correlates well. I sincerely doubt that so little water has any real effect on printing. I wonder if, for those that see a dramatic shift in print quality, that other volatiles are migrating when heated and affecting the print. E.g., warm filament prints better than cool filament.

RE: Drying filament - temperature precision

I'm not expecting there to be any hard rules. These devices are used under such varying conditions that results generated at one location will differ from those generated at other locations. I'm content enough knowing that sudden changes in print characteristics with a given filament can usually be improved with pre-print toasting.

I've only had one spool of PLA do this, and in general don't worry too much about it with PLA, but I'm not about to extrapolate that into any sort of assertion that PLA is immune to storage environmental issues across the board. If I start to get crappy external perimeters or stringing with filament that worked well previously, I do a toasting before I start making hardware or slicer tweaks. I'm happy with that, whatever the root cause.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Drying filament - temperature precision

I had a similar problem and used my dehydration, and then I cleaned it thoroughly so that there would be no further problems using it.