Brown burned filament??

Same apology. I have tried so many photo edits and rotations.

In any event, what does this brown burned filament indicate. It mucked up my print. Never had this happen before. PLA. Have since done some e-axis moves and filament is coming out clean again. But for how long? Time for another cold pull?

Mk3 - 1X

Mk3S - 2X

2021 Hyundai Palisade

Wife - 1X

RE: Brown burned filament??

That's burnt filament dropping into your print. Remove the part cooling fan and inspect the hotend with good light. See if you have old filament accumulated around the hotend. If so, you can use a soft brass brush to carefully clean it off, taking care around the delicate wires. Use a toothpick to clean out around the wires if needed. Look at the top of the heater block and ensure there's no leakage coming out between the heatbreak and heater block indicating a poor nozzle seal.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Brown burned filament??

Indeed, during my nap today it dawned on me that I had a big blob this morning. I thought I got most of the gunk out. Upon inspection now I see there is just a bit more above the heater block. The toothpick is a great idea. Thanks.

Mk3 - 1X

Mk3S - 2X

2021 Hyundai Palisade

Wife - 1X

RE: Brown burned filament??

If you have burnt bits above the heatblock, you may have a leak either above or below the heatblock, causing strings to curl upwards.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Brown burned filament??

What is the most common cause of a leak?

Mk3 - 1X

Mk3S - 2X

2021 Hyundai Palisade

Wife - 1X

RE: Brown burned filament??

I guess that would depend on your type of hotend.

On my Flsun QQs it it a e3d v5/6 j-head mk8 type with hollow heatbreak that lets the ptfe-tube go down and butt up againt the top of nozzle.

I noticed i had quite a severe leak and disassembled it, and found a tiny speck of ptfe granulate. The tube wasn't cut cleanly.

I recut the tube and tried again.

I have now only a tiny leak with one brand of higher end filament that are more runny then the generic pla i normally use.

In my case, it seeps out below the heatblock, in the threads of the nozzle so i let it be for now, and just wipe down the nozzle before each print.

In the case of a non-hollow heatbreak, where the tube only goes partially down inside, and you have metal to metal contact with the nozzle, it might just have come loose after long usage and started to seep thru the threads in the heatblock.

I use a bit of papertowel wrapped around a bit of cardboard to gently clean around the hot nozzle.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Brown burned filament??

I guess that would depend on your type of hotend.

On my Flsun QQs it it a e3d v5/6 j-head mk8 type with hollow heatbreak that lets the ptfe-tube go down and butt up againt the top of nozzle.

I noticed i had quite a severe leak and disassembled it, and found a tiny speck of ptfe granulate. The tube wasn't cut cleanly.

I recut the tube and tried again.I have now only a tiny leak with one brand of higher end filament that are more runny then the generic pla i normally use.

In my case, it seeps out below the heatblock, in the threads of the nozzle so i let it be for now, and just wipe down the nozzle before each print.In the case of a non-hollow heatbreak, where the tube only goes partially down inside, and you have metal to metal contact with the nozzle, it might just have come loose after long usage and started to seep thru the threads in the heatblock.

I use a bit of papertowel wrapped around a bit of cardboard to gently clean around the hot nozzle.

Remove the part cooling fan and inspect the hotend with good light. See if you have old filament accumulated around the hotend. If so, you can use a soft brass brush to carefully clean it off, taking care around the delicate wires. Use a toothpick to clean out around the wires if needed.

RE: Brown burned filament??

That's burnt filament dropping into your print. Remove the part cooling fan and inspect the hotend with good light. See if you have old filament accumulated around the hotend. If so, you can use a soft brass brush to carefully clean it off, taking care around the delicate wires. Use a toothpick to clean out around the wires if needed. Look at the top of the heater block and ensure there's no leakage coming out between the heatbreak and heater block indicating a poor nozzle seal.

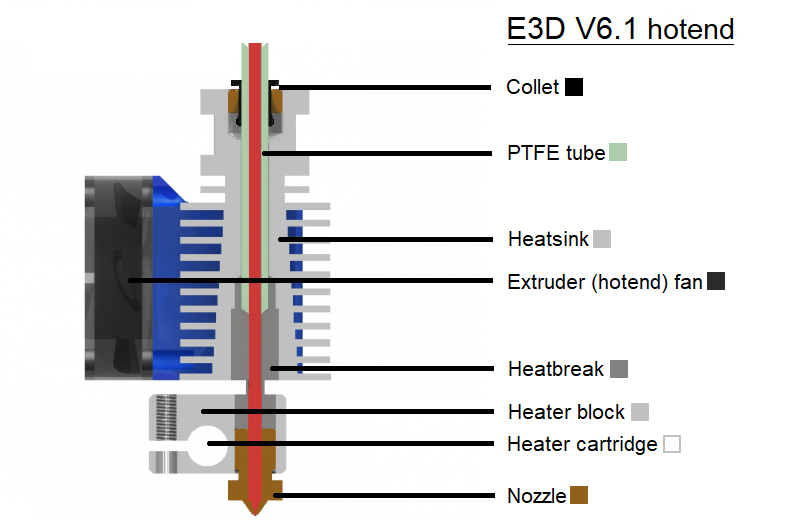

Hi @bobstro , where is the top of the heater block (any photo?) and how to check if there is any leakage coming out between the heatbreak ad the heather block? Is the heatbreak the cylinder-like part that has lots of slots?

RE: Brown burned filament??

Hi @bobstro , where is the top of the heater block (any photo?) and how to check if there is any leakage coming out between the heatbreak ad the heather block? Is the heatbreak the cylinder-like part that has lots of slots?

Here's a good cross-section figure someone posted previously.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Brown burned filament??

@bobstro

Thanks for the nice illustration. Am I correct that if I see some filament at the gap between the Heatbreak and the Heater block, it means there is a leakage? One confusion I have is that Prusa Support asked me to take a photo at the bottom of the extruder. After seeing the photo, he asked me to tighten it. The photo I took only shows the bottom of the Heater block (the surface near the Nozzle). It does not show the area between the "top" of the Heater block in the illustration and the Heatbreak.

I also used a brush to clean the bottom of the Heater block (the area near the Nozzle). Black dots disappeared for a day but then they show up again on the next day. Is this a related or separate issue?

Are those nozzle cleaner useful? I have seen users pushing those thin nozzle cleaner wire from the nozzle hole and up. I wonder if this is useful as such pushing action just pushes those burnt filament more to the inside of the Heatbreak? How does this work?

RE: Brown burned filament??

Those cleaning wires are only needed if you have a blockage.

If melted filament is coming out where the heat break goes into the top of the heater block that would indicate a leak.

When the nozzle and heat break are tightened against each other they form the seal that keeps the melted filament from leaking out.

Have you followed the instructions for tightening the nozzle? It can be a bit of a challenge dealing with the parts at 285°C and also being careful not to put too much torque on the heat break. The heat break is thin metal in the middle and can be bent or broken.

Use the instructions for changing the nozzle to tighten it, just skip the step where they say to take the nozzle out:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle_2069

If tightening doesn't help you may have a nozzle or heat break that isn't perfectly flat where the 2 meet or some debris between them.

RE: Brown burned filament??

[...] Thanks for the nice illustration. Am I correct that if I see some filament at the gap between the Heatbreak and the Heater block, it means there is a leakage?

Yes. The only way filament can collect up there is if it oozes out the top of the block.

One confusion I have is that Prusa Support asked me to take a photo at the bottom of the extruder. After seeing the photo, he asked me to tighten it. The photo I took only shows the bottom of the Heater block (the surface near the Nozzle). It does not show the area between the "top" of the Heater block in the illustration and the Heatbreak.

Support always has to balance their need for information with what they can reasonably ask upset users to do. Taking a picture of the underside is simple enough. Removing the cooling fan shroud and getting light into the gap between the block and heatsink is more complex. Looking at the underside, they can probably determine if filament is oozing from "somewhere" besides the nozzle itself, that alone is sufficient to diagnose a poorly tightened nozzle with relative certainty.

I also used a brush to clean the bottom of the Heater block (the area near the Nozzle). Black dots disappeared for a day but then they show up again on the next day. Is this a related or separate issue?

Probably related. The dots can come from the leak on top, or filament catching during printing underneath. The leaking can aggravate the catching as a tiny bit of leaked filament can snag printed filament and compound the problem. The dirtier the block, the worse it gets. I really wasn't aware of this starting out until I realized my block was filthy. I started cleaning it, initially with a wire brush and later using a strip of corrugated cardboard as a "squeegee" to scrape off accumulated filament. After adding an inexpensive silicone sock to my heater block, the problem is resolved. When I remove the sock, the heater block looks almost new.

Are those nozzle cleaner useful? I have seen users pushing those thin nozzle cleaner wire from the nozzle hole and up. I wonder if this is useful as such pushing action just pushes those burnt filament more to the inside of the Heatbreak? How does this work?

I'm not a fan with the needles and bits. They work, sure, but they can also damage the nozzle, leading to more frustrating problems. They also poke the problem further up into the nozzle and heartbreak where it can simply work its way back down and block everything later. I also snapped off a needle inside the nozzle which really added to my frustration.

That was when I did some research into the "old ways" and discovered cold pulls (also called atomic pulls). Instead of poking the blockage up out of the way temporarily, a cold pull procedure melts cleaning filament inside the hotend and nozzle and lets it harden to trap any debris. Then it is heated up and pulled out the top while still flexible. This removes the debris instead of just poking it up out of the nozzle and into the hot end. I personally prefer to use eSun cleaning filament, but you can do a pull with any filament. Some are stretchier than others and will work better. The key is to get a good impression of the inside of the block and nozzle. This way, you know you've pulled everything out.

I recommend a cold pull for routine cleaning, and every time you switch from a higher-temp filament (e.g. PETG) to a lower-temp filament (e.g. PLA) as the higher temp stuff won't melt out during a print, and if any is left behind, can result in a partial clog. The cleaning filament is very flexible and will also melt over a wide range of temperatures, so if a bit gets left behind, it won't cause problems next time your print PLA.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…