RE: Underextrusion

Thank you all for the great community and sharing of experience and best practice. After moving the heat end up a couple of times, I now reached a state where it prints again. Hopefully for longer than before. For me, it got stuck the first time half way through the Prusa logo print after setting the thing up and it was very, very disappointing. I also spend 10+ hours trying to fix it.

RE: Underextrusion

My printer is now working. My underextrusion was solved after I loosened the spring from the filament feeder. The screw top needs to be level with the plastic. That seems to be the optimal position since any other position gives underextrusion. Also I took the extruder apart wholly and built it again. Also I removed all bowden tubes I could and repositioned them / tightened.

Not sure what was the main cause, but doing all the work again that the factory should have done, helped..

RE: Underextrusion

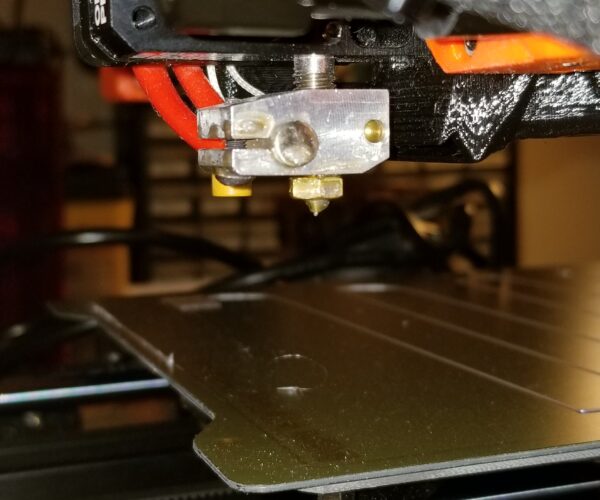

Similar to another post, my extruder looks like this.

My printer has been out of operation for about a week due to a damaged sensor, (well hopefully that's the problem, I just received the replacement today). Now that I am about to install the sensor, I wonder if I should see if this is an issue as well. Thus far I printed all the sample prints, and they seem ok, until one poster said the bottom of the prints are supposed to be very smooth. Mine look like this:

I'd like to lift the heat block, but someone in another thread said it should be 4.8mm from the heat sink.

Forgive the excessive questions, this is my first FDM printer, and I'm new to 3D printing as a whole. Just want to make sure I get this thing dialed in correctly.

Any suggestions?

Should I loosen the 3 screws and lift the block? Just replace the sensor and see if it was a Z height issue?

RE: Underextrusion

[...] Thus far I printed all the sample prints, and they seem ok, until one poster said the bottom of the prints are supposed to be very smooth. Mine look like this:

Your Live-Z is too close to the bed. Try raising it (I'd go up starting at 0.04mm and in increments 0f 0.02mm) until those ripples even out. You're close, just need a bit of tweaking. Nothing major to worry about.

RE: Underextrusion

@deutsch-jacob

If I compare mine to your and the photos from previous pages, mine looks just same. Too low.

https://help.prusa3d.com/article/e6tym5n457-clicking-extruder-mini

There is even a help site related to this problem. Again, yours and mine looks like the "Bad!" one, but if I measure, I have the mentioned 4.8mm between heat-block and heat-sink.

Could someone from Prusa confirm, if the 4.8mm is right. Cause on the photo, the thread is just 1mm below the heat-sink.

RE: Underextrusion

I have these exact problems with my Prusa Mini (probably one of the machines in the first batch out). I've adjusted the tension screw, taken the bowden assembly apart, cold pulled, checked for clogs, I'm not able to get the machine printing reliably. Like others have reported, I have about 50 hours of good printing out of the machine before clicking/no extrusion. Removing the filament, reloading, and restarting a print always seems to work for about 45-60 minutes.

I'm trying to reseat the PTFE tube as others have said while also keeping the nozzle tucked up as close into the heatblock as possible, following the video and advice in this thread. I noticed that the PTFE installed is a few mm shorter than the spare, and the spare was at the spec 43.xmm. Question: When I try to install the spare at the "correct" length the nozzle is at least 5mm off what the pictures posted in this thread show, or, if I have the grub screws tightened, it doesn't feel possible to tighten the bowden nut correctly. I'm worried about damaging the assembly. How much force/how easy should it be to install the PTFE tube that is at the specified length?

Currently feeling very frustrated with the Mini. My MK3S kit has been in near-constant operation the last couple years, I've already had more repairs (thermistor, lcd, control knob, now this) with the Mini than I've ever dealt with the MK3S. Still waiting on my support email to get a reply as well.

RE: Underextrusion

If you have short PTFE tube, then the heat break threads will hit the heat sink and the PTFE will be loose. Filament will collect under the PTFE and cause inconsistent extrusion.

As long as you ensure that you clean out all the plastic between the PTFE and seating in the heat break and when re-assembling, the heat break threads do not touch the heat sink, you should be OK. Just follow the re-assembly instructions.

The PTFE length should be 43.4mm (+0.15/-0.10) in length.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

RE: Underextrusion

Ok, I'm going to do another 275 degree burn, cold pull, and install the 43.4mm PTFE tube. Like I said the PTFE that came installed was about 39mm long (and shows a little wear/melting on one end). Thanks Peter.

RE: Underextrusion

I'm also having underextrusion problems with PLA (blue Prusament I ordered with my MINI) after couple of hours of printing. PETG (white Gembird) print was ok overnight (there were some stringing, boogers and other common PETG issues, but not underextrusion).

I seem to already have R2 of the printer. There is around 4,5 mm between hotend and heatsink (might as well be those 4,8 mm, but I don't have presice measure). It fits there pretty tight, no rattling or somehting when I tired to move it by hand. But I coulnd't check those 3 bolts are tightended, because I lack the required tool. I also checked my PTFE tube, it seems flush with top of the heatsink. I had some touble pulling it out (it fits in the hole very tightly), but it was clean on both ends.

But i also noticed a lot of white dirt from PETG in the extruder gears. Like, a lot for just couple of nights printing.

I already tried to cleaned it once, but then just printed this PETG. So I guess I'll have to do it again.

I'm a but disapointed at this point. Having to clean the hotend every couple of days is not ok, in my opinion. This is my first printer, and I thought the dechnology and processes are now at the point whre the printers are not expensive and you don't need to fiddle and mess with it every couple of rpints. Look like I was wrong.

RE: Underextrusion

To check you need to remove the PTFE tube and look down into the heat break.

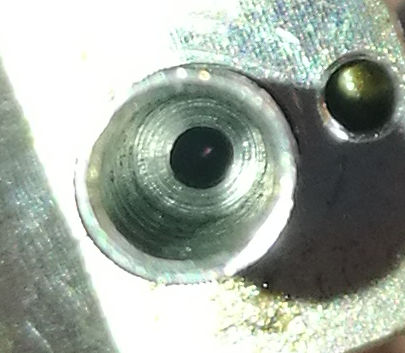

You should see this:

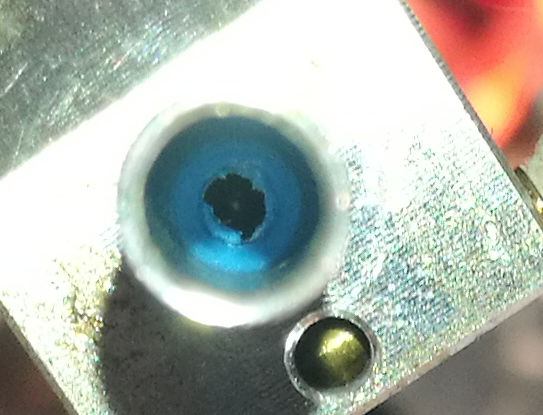

And not this:

If you see any plastic at all, then you need to clean it out and follow the instructions precisely to reassemble.

The allen key required for the grub screws has been included in the tool kit provided with the printer.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

RE: Underextrusion

@pjr

How can I get such a nice view? I already tried removing the tube and looking down, but I couldn't see anything. There is like 5 cm long black hole through the heat sink/fan and I just wasn't able to place the light to see what's at the bottom.

About that allen key, I found just one, for the assembly of the printer and it's too large. Maybe I'll check the bags again :).

RE: Underextrusion

@pjr

How can I get such a nice view?

You need to remove the hot end from the heat sink, remove PTFE and just use your smartphone camera with flash permanently on, focus on the heat block.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

RE: Underextrusion

I'm not sure if there is something like this at other threads.

My Mini was not able to print even a calibration pattern with a provided PLA sample, now it works gorgeous.

The solution is exactly in the distance between a heater block and a radiator - a default space is to big to create a well-shaped solid/liquid transition in the filament. I believe that 5mm gap is enough to form a viscous plug that tries to solidify at the PTFE tube - I've found that when the unload feature left a part of this at the bottom of the hotend's PTFE.

Next part was a super 'counterintuitively' for me.

The total length of the PTFE tube and other elements show that the top end of the tube should be right as the top surface of the radiator. But! I removed a fitting, then moved the hotend 2mm upwards according to Olef comments (now I have 3mm gap), and carefully tried to install the fitting back. I haven't feel a significant counterforce during a fitting installation, and tightened it all down. It feels a bit strange that 2mm of the PTFE tube was just compressed, but a filament channel was still free and I was able to manually feed the filament through the heater block. You can try to use some washers under the fitting if described above looks scary.

An only other modification was a new bowden tube, because a filament tip during an unload was too big for the tube. My cheapest noname 4/2mm PTFE tube works just great.

PS: Please, use a reasonable force to your printer, if it feels like a need of more force than to open a Cola bottle - think again if you need to do this. =)

RE: Underextrusion

To check you need to remove the PTFE tube and look down into the heat break.

You should see this:

And not this:

If you see any plastic at all, then you need to clean it out and follow the instructions precisely to reassemble.

The allen key required for the grub screws has been included in the tool kit provided with the printer.

Peter

My Mini printed great for weeks with several dozens of prints. Some were over 24 hours. Suddenly, I began having all of the issues described in this thread. Tried a new nozzle, new PTFE tube, etc. Nothing worked. UNTIL, I looked at the bottom of the heat break and saw what you are showing. When I replaced the PTFE tube, I though I had it pushed in all of the way, but I had seemingly only seated it on top of the melted plastic. I'm not sure how this happened after so much time, but after burning out the excess filament and making sure the heat sink was squeaky clean, then following the assembly instructions I seem to be back to a working mini. I'm 13 hours in to a 14 hour print with no issues. Thanks for this!

RE: Underextrusion

@andrew-d44

try this one yet?

RE: Underextrusion

I am trying to make this adjustment and I'm having a frustrating problem with those grub screws. Specifically, I chatted with support to confirm that they are 1.5mm, and after my cheap 1.5mm key wouldn't unscrew (it slipped when I added torque) I went and bought a brand new 1.5mm key and it also is slipping in the screw. Given the torque that seems to have been applied I wonder if they were stripped on assembly.

So I'm at a loss for how to make this adjustment, and I'm not even sure how to proceed at this point.

RE: Underextrusion

It makes sense what you guys are saying. One way or the other, the stuff is too cold and/ or dust clogged. Then, the motor keeps pulling on material that does not want to move.

Thanks

RE: Underextrusion

@corywest

I assume they are still sticking out a bit from the heatsink? You can use a small metal saw (with one of those blades that stick out) to saw a slot in them, and then use a flat screwdriver to get them out. Replace them with standard m3 bolts, there's plenty of room for the heads of the screw to stick out. Prusa probably only went with grub screws so people would be careful and not overtighten them.

RE: Underextrusion

@stevensmith

can you describe your procedure? thank you

RE: Underextrusion

Received my mini yesterday and had same issue. I moved up the heat block to get PTFE tube to fit correctly, and the “blob” that gets stuck in the hot end has gone away.

However, I still have never successfully completed the first layer calibration using the provided Prusament PLA samples. The extruder clicks/grinds at the PLA preset temperature. Filament does not flow unless I manually increase hotend temperature to about 240C

Does anyone have any ideas?

Thank you,

David