RE: Underextrusion

@crawlerin

Feels like it, doesn't it? Any filament other than Prusament becomes jammed or has other problems. Sensorless homing? More like magic sensorless DRM, as a feature. It's kind of incredible.

I don't have many filament types, but I'd be curious to compare the physical characteristics of Prusament versus other PLA manufacturers. The one thing I immediately notice is that Prusament has a very textured surface while other manufacturers are smooth. Another thing is that when pulling out failed alternative filament, it's almost always covered with very fine PLA dust (a byproduct of the Bowden grinding).

RE: Underextrusion

@m8harry

Try increasing your first layer height. I have mine set a .3mm with prusament. The new PEI sheets have some sort of weird linear texture which causes the filament to ball up if you are too close. The smooth sheet with the MK3 was completely smooth. The mini sheet has vertical 'ribs'.

RE: Underextrusion

@brad-w2

Thanks for the pic, your hotend is about 5mm higher up than mine.

To get mine up that high I'd need to cut a bit off the ptfe tube, I'll give it a shot. At this point, it can't really hurt.

On a side note, my spare ptfe is about 2mm longer than the one that's currently in the hotend

RE: Underextrusion

@m8harry

I'm using 3dfillies pla+ too, all of which prints beautifully on my mk2.

The only filament other than prusament I can get to print is a cheap roll I got from Ebay

RE: Underextrusion

Prior to this the prusament printed fantastic on supplied and my own sliced models

Prusa does not even need to chip their filament, this is some kind of hardware-based DRM 🤣

Hahahahha, it sure seems this way at the moment

RE: Underextrusion

@g-j-sieben

I noticed the same thing, the prusament is very dry with a matte finish.

Initially I thought this may be what's causing the jams but, I have a roll of cheap ebay filament that is currently working on the mini that is glossy and a little undersized (1.70mm).

Maybe it's a combination of issues, matte filament works better and there's some issues in the hotend.

I'm going to try a couple of things today

RE: Underextrusion

@brad-w2

Thanks for the pic, your hotend is about 5mm higher up than mine.

To get mine up that high I'd need to cut a bit off the ptfe tube, I'll give it a shot. At this point, it can't really hurt.

On a side note, my spare ptfe is about 2mm longer than the one that's currently in the hotend

I took the PTFE tube out and did a couple of cold pulls and pushed the hot end up. This resoled my Underextrusion issues for now. When I was installing the PTFE tube I also noticed that for my nozzle to sit higher I need to cut the PTFE tube. I think that the problem is that the PTFE tube is to long and when you Re-attach the bowden fitting to the heatsink in put pressure to the PTFE tube and push the hot end assembly down causing filament path problems that make underetrusion problems. I think Cutting the PTFE tube will resolve the issue and will let the hot end sit up higher.

RE: Underextrusion

@brad-w2

@chris-b2, perhaps if @brad-w2 is correct above, you could try printing using the Mini PEI sheet on the MK3S (assuming you have one). There seems to be a small chance to me that if the sheet is different, you would also have issues on the MK3S if it was truly the sheet.

RE: Underextrusion

@g-j-sieben

Unfortunately I have an MK2 so I can't try that, but I'm going to try the smooth pla sheet, so far I've only been using the textured one

RE: Underextrusion

This may be a long post but I think it is worth making as it may give some of your some insight into this issue. I have spent several hours on this including about two and a half hours on Prusa chat support. What we discovered was significant for me and hopefully for others too.

I disconnected the bowden and tried to manually feed PLA through the nozzle. This failed. I took out the brass M/M adapter and the short PTFE from the heatsink. Still I could not feed PLA - nozzle seemed to be completely blocked. Talking with Prusa support they suggested heating the nozzle to 290 degrees, and after a few minutes at that temp I could finally push through PLA. Out came a large blockage then PLA was flowing. It flows pretty well at 290 degrees!

Then support had me step the temp down by ten degrees at a time and test. I could still push through PLA down to about 240 degrees so something was still not right. That is way too high for PLA.

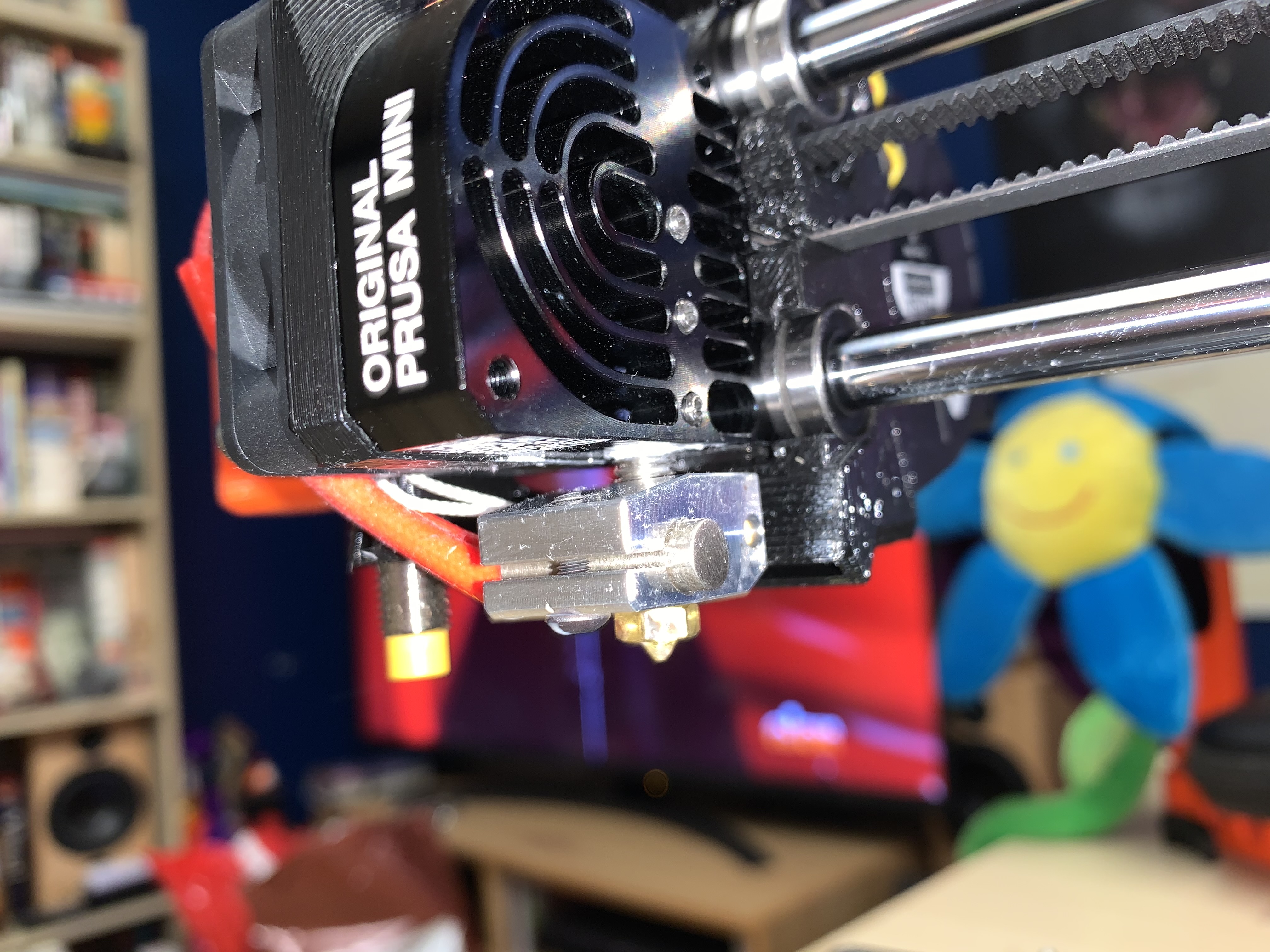

Working with support then we stripped down the hotend by undoing the three grub screws, re-inserting the short PTFE then pushing the hotend fully back up into the heatsink, then tightening the grub screws. This produced quite a marked change. The image below which I posted earlier is the before -

And this image is after the adjustments -

You can clearly see the difference. The hotend was never fitted correctly and set up, so there would have been a void between the metal and the short PTFE. I believe this was allowing melted plastic to gather there and jam up the extrusion.

After setting up the hotend as above and tightening the grub screws, the final part involved fully inserting the short PTFE than replacing the brass M/M adapter. This had to be tightened fully and the backed off a quarter of a turn.

My next action was to disconnect the extruder idler and open it, then clean out all the shredded PLA. I then reconnected the idler and took care not to over tighten it. My idler can still be pushed with an allen key against its spring whereas out of the box it was almost fully tightened. Something else not adjusted correctly.

Because I had moved the nozzle I did a factory reset and full self test, then set the printer up from scratch including resetting the MINDA height to a credit card width and doing a full first layer calibration.

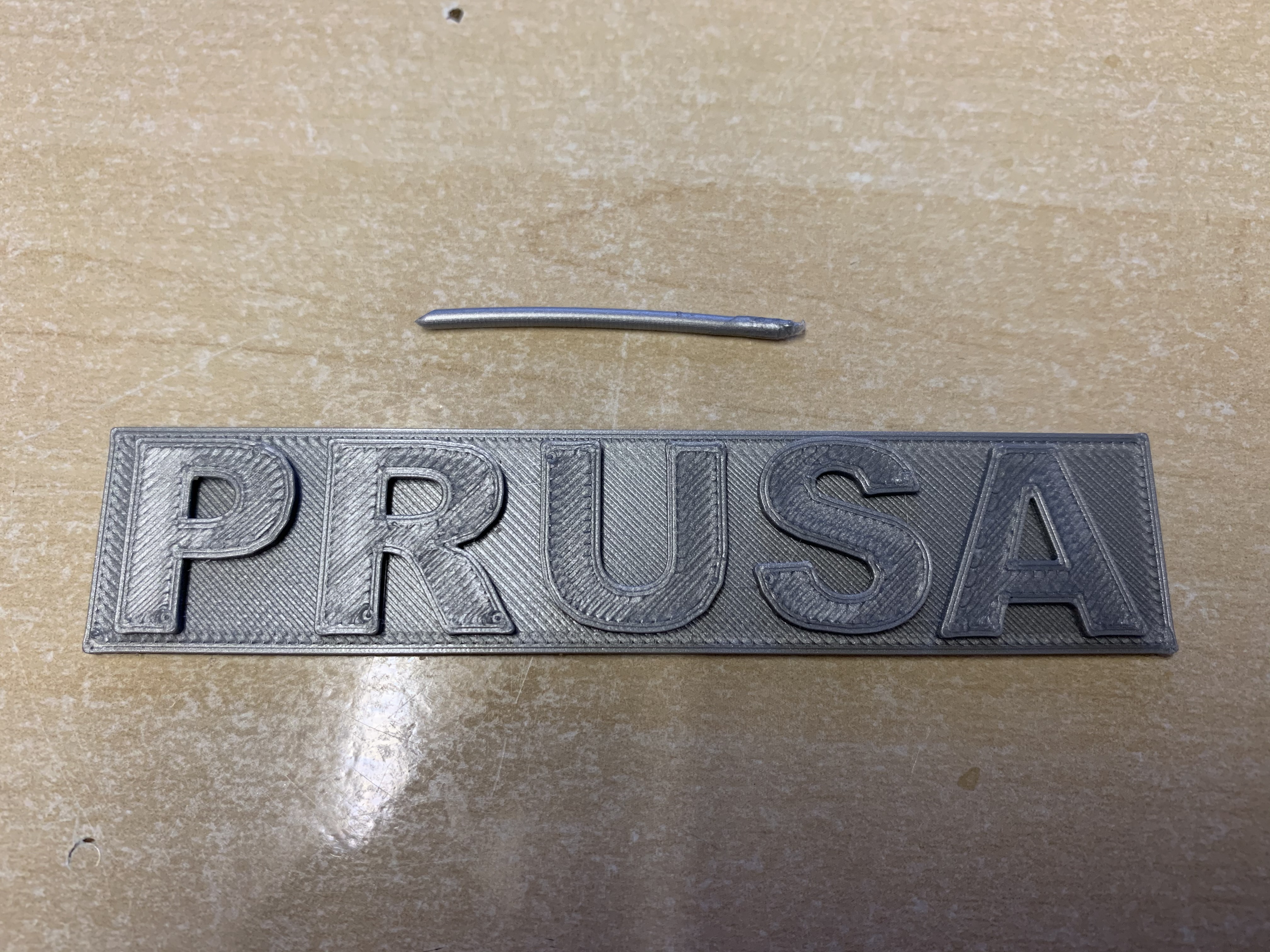

Lastly with fingers firmly crossed I tried to print the Prusa logo off the USB stick. This time it printed perfectly, better even than on my Mk3S's. Here it is, and also here is the end of the filament I unloaded after the logo print. As you can see there is no bulge, just a properly formed end which unloaded without issue.

In conclusion then my printer was sent to me in a poorly assembled state. It was not assembled correctly or set up from the factory, and the possibility of this is not covered in the assembly manual.

Obviously I am aware this is one of the early units and there are bound to be teething problems. But this printer is being marketed as an ideal starter printer and so it should work out of the box. I believe Prusa Research need to urgently address their Mini assembly and setup procedures and also amend their documentation to cover issues such as this. Someone new to printing would probably not have invested the time and effort into making this Mini work and may have been discouraged completely.

Although it has taken eight days at least I now have a working printer, or will have when Monday comes and the replacement parts arrive!

RE: Underextrusion

@olef

Thank you for the detailed post, I'm currently in the process of doing the above.

Did you need to cut the ptfe? I'm trying to work out the new length it needs to be after pushing the hotend up

RE: Underextrusion

@chris-b2

No I did not cut the PTFE, it fits as it is. Good luck!

RE: Underextrusion

@olef

So almost any PLA filament works now, and not just Prusament?

RE: Underextrusion

My testing was done with PLA from 3DPrintz UK, which now works fine.

RE: Underextrusion

I m talking to support right now PTFE Tube should be 43 mm long.

RE: Underextrusion

@olef

Is this a potentially warranty-covered issue, you believe?

Also, because I (and no doubt others) are new to 3D Printing, could you consider making a short video showing what needs to be done?

RE: Underextrusion

The mini is currently printing after raising up the hotend, yay!

I had to cut a little off the ptfe to make it fit with the new hotend position, but so far so good.

I'm still getting a crackling sound from the hotend, which had been there all along, not sure what that is.

And, it's just clogged while I'm writing this. Dang it.

Managed to do half a Prusa logo, which is an improvement.

🙁

RE: Underextrusion

@chris-b2

Glad you have some progress. Re the PTFE I'm surprised you needed to trim it, I believe it should be the correct size to prevent any gaps when tightened down. Perhaps try again with the spare one? I think someone above posted the correct length as advised by support.

@g-j-sieben

I personally would not consider machine setup and calibration a warranty issue, but I have seen in the past Prusa have taken back machines to test, repair if necessary and calibrate. If you are having difficulties chat support is your first call, they are very responsive and have always dealt with my queries in a professional and helpful manner.

Re video I am flattered by your confidence in my abilities but I think that any setup guide should be produced directly by Prusa - they have in depth knowledge of the design and its capabilities. I am just another user who enjoys Prusa printers and I try to pass on any knowledge gained via the forums. If your new printer is not behaving as it should please give chat support a try - they are very good at what they do!

RE: Underextrusion

You should not cut the PTFE tubing.

Remove the Bowden connector at the top of the extruder

Remove the short PTFE tube.

With a torch, check that there is no filament remnants in the heat break. If there is, heat the extruder to soften the remnants, insert filament and pull out (remnants should stick to the filament). Cool extruder before continuing.

Insert new PTFE into heat break; push down fully.

Loosen the 3 heat break grub screws.

Connect the bowden at the top of the extruder and tighten. Then BACK OFF one quarter turn.

Push the heat break up from the cold nozzle and tighten the 3 grub screws.

Tighten the bowden connector by one quarter turn.

Check the MINDa height.

Calibrate first layer.

With regard to the MINDa, the cable tie above the extruder fan should not be over-tight and there should be a small loop of MINDa cable between the cable tie and the probe to ensure that the MINDa does not move slightly with X axis movement.

Peter

Please note: I do not have any affiliation with Prusa Research. Any advices given are offered in good faith. It is your responsibility to ensure that by following my advice you do not suffer or cause injury, damage…

RE: Underextrusion

These are all good advice and I’m now onto my 18th hour of printing with black PETG, the Solutech brand from Amazon with zero issues.

I think if you dial in the machine as suggested above, the insensitivity to filament is reduced, at least for PETG.