RE: Underextrusion

@chris-b2

Yeah my MK3 is superb with anything. The Mini is very sensitive and several people have noted the same finding as you.

RE: Underextrusion

@andrew-d44

Yeah, it's a shame, I really want to like this printer, but it's current inability to print anything and it's sensitivity to different filaments is a real deal breaker.

RE: Underextrusion

@chris-b2

I’m 100% in agreement. I’ve some different Bowden tubing on order and I’m going to play with that to see if any difference. Doubt it would even come close to solving the issues you are having.

RE: Underextrusion

@andrew-d44

Are you currently able to print with anything other than prusament?

RE: Underextrusion

@chris-b2

At this point I’m not even able to unload the filament without a tonne of messing around with Pronterface. As my control encoder is completely broken.

I was going to try a Solutech PETG this morning but gave up as I can’t live z or eject the prusament PLA. Now I’m shelving the machine until Prusa get back to me.

RE: Underextrusion

@andrew-d44

That sucks, I had a broken lcd knob too, I'm using the replacement now.

I found that filament can be removed by pushing against the idler from the back to release the tension on the spring, but that won't do you much good when you cant control the printer

RE: Underextrusion

I took off the bowden tube and manually feed prusament pla into the hot end. It seems there is not enough cooling at the heat break. The melt zone is about 25mm long. I believe that with retractions this is what is causing the jams and underextrusion. I wonder if the cooling fan is at 100%?

RE: Underextrusion

I figured it out with y'alls help. My whole hot end had dropped out of the heat sink due to the loose grub screws. This caused the melt zone length to extend and the filament to fill the gaps between the heat break and ptfe tube.

I had to disassemble and do a few cold pulls to clear everything out. I loosened the grub screws and pushed the hotend as far up as I could. Then tightened down the bowden tube down. Had to adjust the probe and recalibrate.

I did another cold pull and can still see the seams between the ptfe, heat break, and nozzle. It seems to be fine now.

RE: Underextrusion

@brad-w2

Fantastic! I think this was my issue too. I also noted a rather large melt-zone before I did several adjustments and in the end couldn’t figure out exactly which one was my main issue.

Maybe this is the issue that Chris has?

RE: Underextrusion

@andrew-d44

Good to hear you guys are having some success.

I've done as much as I can at the moment I think, with two of the grub screws being threaded I'm not able to do much.

I've removed the ptfe in the hotend and removed a small ring of pla that was underneath it.

Still having the extrusion issues though, although it's seems to have improved a little, I've managed to get one roll of filament to print.

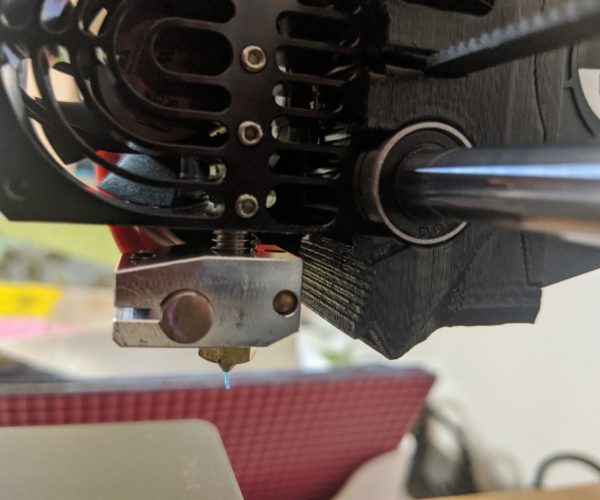

Can one of you please post a photo of your hotend and I can compare how low it's sitting to mine?

RE: Underextrusion

Interesting, maybe you are onto something?

RE: Underextrusion

@olef

Thank you, it looks about the same as mine.

I managed to remove my oversized grub screws using a 1/16 allen key instead of 1.5mm. My hotend it as far up as it'll go, and still won't print for much more than one or two layers of the prusa logo.

Back to the drawing board 🙁

I spent some time with chat support again today and they're out of ideas, and suggested that I return it.

RE: Underextrusion

@olef

Thank you, it looks about the same as mine.

I managed to remove my oversized grub screws using a 1/16 allen key instead of 1.5mm. My hotend it as far up as it'll go, and still won't print for much more than one or two layers of the prusa logo.

Back to the drawing board 🙁

I spent some time with chat support again today and they're out of ideas, and suggested that I return it.

Support's response does not sound good at all. I'd be interested to know if you do decide to return it. I'm going to sit it out for a while with mine in the hope they find the answer as I do have other Prusa's I can print with. In the end if they can't figure it out relatively quickly I'll probably ask for an RMA and pay the difference for another Mk3S. I know they work!

I wonder why this did not show up in the beta tests? I hope there are no new users struggling like this, it would not be a good introduction to 3D printing. Even my very first printer, an Anycubic i3 clone, would actually complete prints.

RE: Underextrusion

@olef

Yeah, I'm quite surprised that these issues are occurring. I'm not really sure if I should request another unit or a refund

RE: Underextrusion

Is there any possibility that there are gaps in filament path, and it just jams somewhere inside hotend assembly? This is what Chris wrote:

I've removed the ptfe in the hotend and removed a small ring of pla that was underneath it

RE: Underextrusion

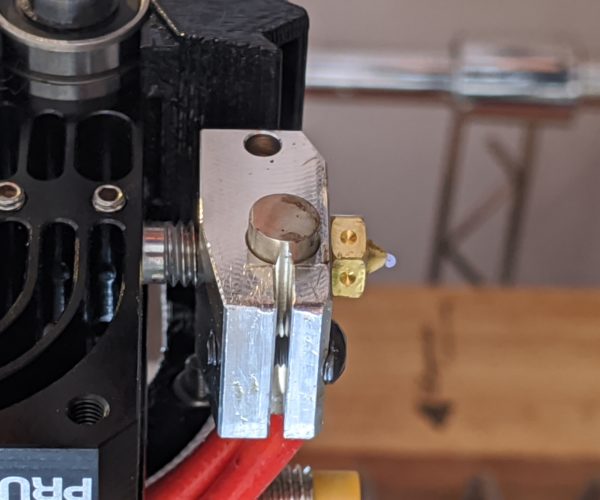

Here is my hotend and sample prints after the fix.

RE: Underextrusion

Interesting. I'm having issues with 3d fillies pla+

It jams and first layer calibration test square has blobs on it. Tried printing the supplied frog and I had the filament ball up in the hot end and not extrude.

Prior to this the prusament printed fantastic on supplied and my own sliced models

I will try some of the fixes posted.

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Underextrusion

Prior to this the prusament printed fantastic on supplied and my own sliced models

Prusa does not even need to chip their filament, this is some kind of hardware-based DRM 🤣