Under extrusion issue and solving

Hi everyone,

I want to share my experience in order to help others.

I receive my Mini, 4th printer of mine.

Followed the quick installation guide, followed the software first print guide and so on.

Here it comes to the first print, the Prusa logo. It worked wonderfully.

Then I printed the screw. It went pretty good with some minor errors.

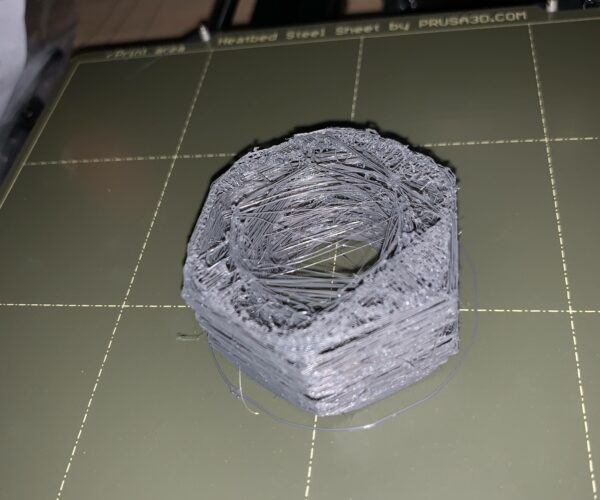

Then I wanted to print the bolt and here came the issue. Not possible anymore to do any print.

I restart the procedure, cleaned everything... nothing work.

Then I look at under extrusion topic and one worked for me. The guy did a video, but one picture is enough for this matter :

First unscrew the top bolt that guides the PTFE tube.

Then unscrew the 3 small screws without head.

Pull off the PTFE tube, clean it up (for me it was perfectly clean).

Then push up the hot-end to its maximum level.

Put back the PTFE tube inside, then screw everything back.

Tada ! It worked now. Do not forget to do the Z procedure since the hot end moved. You may have to move also the Z sensor as well.

Good luck everyone.

RE: Under extrusion issue and solving

Now if there was a way to pin this thread that might save a lot of time...

RE: Under extrusion issue and solving

Hello,

I followed your instruction, because i had some problem on my Mini (after 10 successfull printing) :

-I have the extruder with dust powder... probably because the filament cannot come out the nozzle (or just before)....

-The first layer is ok, and after no filament is printed...

-The motor sound toc toc sometimes...

SO i followed, but now when i put the hotend in the maximum position, the nozzle is too far from the bed, even if i put to -2.0....

It's a problem with the nozzle ?

I can make a video, maybe it will be clear.

RE: Under extrusion issue and solving

How is it possible you are so far from bed ??? I think because you did not move the Z sensor up.

The z value correction is the difference between the Z sensor and the nozzle.

but that is not the reason why you would be able to print first layer and not the other...

The noise of the extruder "tac tac tac" is something else, you should look at the extruder part. Maybe you tighten too much a screw on a pife tube so the extruder does not have the strength to push the filament.

RE: Under extrusion issue and solving

When we changed nozzle or set the heatsink, we just need to make the Z calibration right ?

RE: Under extrusion issue and solving

if you change the nozzle yes, just new z calibration.

But here it is a little bit different, you change a lot the nozzle position, so it may be needed to push up the Z sensor as well to not have a too much z difference as you had.

RE: Under extrusion issue and solving

I dismantled everything, and reassembled, especially on the extruder.

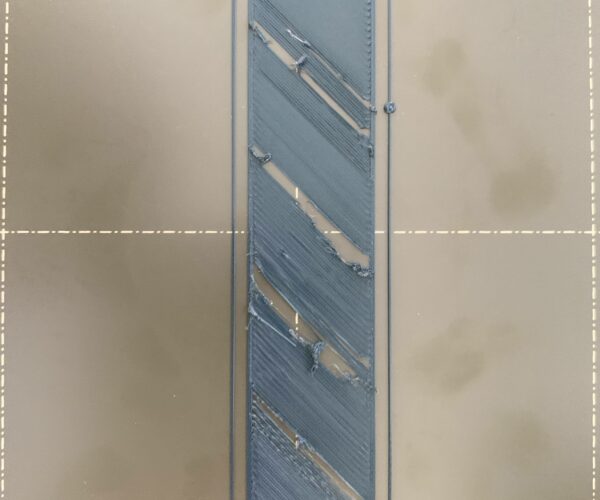

It's almost good, except that I have a leak above the hotend, but the printing of the calibration works, I'm at -1.5 there.

WHAT have I forgotten?

Below the YOutube video, we can see the leak.

RE: Under extrusion issue and solving

Sorry I looked twice but I do not see the leak you are talking about. Sometimes a pictures is better to understand by showing the issue on the photo.

but from what I saw on the video, the brim is not good, so first of all your z calibration is not good, your nozzle is too far from

the bed

RE: Under extrusion issue and solving

I had filament above the hotend. Problem solved

Now i have a clogged nozzle after first layer...

RE: Under extrusion issue and solving

Thanks for the solution. I wanted to do the same, but unfortunately the 3 grub screws holding the hotend are stripped (either the printer came like that, or my tools - albeit not the greatest quality - that work just fine everywhere else, instantly stripped them the second I touched them). I'm not quite sure what are my options to loosen those screws now. Any ideas? Thanks.

RE: Under extrusion issue and solving

Thanks for the solution. I wanted to do the same, but unfortunately the 3 grub screws holding the hotend are stripped (either the printer came like that, or my tools - albeit not the greatest quality - that work just fine everywhere else, instantly stripped them the second I touched them). I'm not quite sure what are my options to loosen those screws now. Any ideas? Thanks.

Thats something I noticed too, I managed to loosen 2 screws but not the last one. I cleaned hotend (removed tube, heated up, removed any plastic that was left there) and printing currently first layer with 240C and next ones at 235C.