Troubles with underextrusion

Hi,

I recently received my first printer, a Prusa Mini. I am still trying to get to know my printer and printing in general.

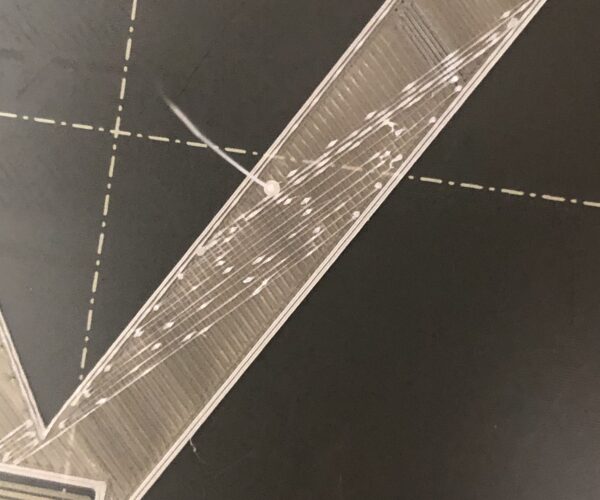

I am suffering with a quite bad underextrusion, that I cannot seem to fix. I have searched quite a lot, and at this time I have tried anything I have found in my search. All with no luck. As you can see in the pictures below the prints (PLA) are actually useless. If I set the printspeed to about 15-20 the result becomes better, but still with some underextrusion (and a really slow process). I have just adjusted the heatsink so the gab is around 4,75mm, instead of the 5,1 when I received the printer. But that didn't help with this.

The first layers are mostly fine, and suffers just a bit.

Anyone know what I can do to avoid this mess?

RE: Troubles with underextrusion

Hello,

I'm having the same problem with 1 of the 3 mini's my school bought... I notice that the filament get's stuck because of the temperature... If I raise the temperature, I can extrude better... But 260° C isn't the right temp for PLA...

seems like a firmware problem?

Greets

Steven

RE: Troubles with underextrusion

Hello,

I'm having the same problem with 1 of the 3 mini's my school bought... I notice that the filament get's stuck because of the temperature... If I raise the temperature, I can extrude better... But 260° C isn't the right temp for PLA...

seems like a firmware problem?

Greets

Steven

RE: Troubles with underextrusion

Hi Steven,

at rest, does the printer show the same temperature for both heatbed and extruder?

is the thermistor fully inserted and tight in the heater block? (Check whilst cold)

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Troubles with underextrusion

So, I actually managed to get a single quite good print last night, after taking the extruder apart and put it back together.

But that was it. Everything I have tried today was severely underextruded. Sometimes I hear the clicking sounds from the extruder.

I have tried serval cold pulls, tightening and loosen the extruder-idler, same result wether it is loose, tight, or in between. There are no filament stuck in the extruder (took it apart again today).

I am getting a little desperate by now. I guess the Prusa Mini wasn't the right choice.

RE: Troubles with underextrusion

Steven, have you checked the length of the hotend PTFE-tube?

I just realised that the one installed in my printer was 41,9 mm. It should be 43,4 mm. I have replaced it with the one from the spareparts, and testing right now.

I hope this do the trick, will let you know.

RE: Troubles with underextrusion

It seems the PTFE replacement did the trick. I have been getting quite nice prints, with no underextrusion, extruder noise, stuck filament or the other problems I had.

I just hope Prusa will use the correct length PTFE tubes in the future, so every new Prusa Mini customer won't have to bother with this.

RE: Troubles with underextrusion

I am having this same problem but with a specific filament and it defies all logic. Similar symptoms, some filament lays down then underextrusion begins, then it's almost entirely blocked (tiny droplets manage to squeeze themselves out while the extruder motor clicks/grinds against the filament). I also can get it to lay down filament when this occurs when I ramp it quickly to 245C but it still prints like crap.

Interestingly enough, it seems to be a filament-specific problem for me, I tried another brand and stopped having this issue. Then I switched back to the previous one of a new color, and the problem is back (this same filament works flawlessly for me in the MK3s I have right next to the Mini at an appropriate temperature of 195).

I've tried print temperatures from anywhere between 190 and 250 with this filament. I've tried increasing flow, decreasing flow, increasing extrusion multiplier, decreasing extrusion multiplier, I've raised and lowered the print nozzle to where it's definitely impeding the flow of filament and up to where it is not adhering to the print bed at all, I've sped it up, slowed it down, used fan, not used fan...

Is the PTFE not long enough and thus some filament is melting at the top or something?

RE: Troubles with underextrusion

Is the PTFE not long enough and thus some filament is melting at the top or something?

Yes, PTFE too short and filament melts at bottom and forms a a plug between heatbreak and PTFE tube. Really this is just a design flaw in the Mini hotend. Increasing the print temp will put more heat into heatbreak and help soften that plug. Different batches filament will have slightly different thermal properties, and the colorant may also have an effect.

Bottom line is make sure the PTFE is the right length and readjust heatbreak, MINDA probe as necessary.