Stringing! how to fix that?

So after fixing numerous issues with the mini i have it printing some what good. The makers muse tolerance test printed great! all 5 parts turn freely and the center can be removed!

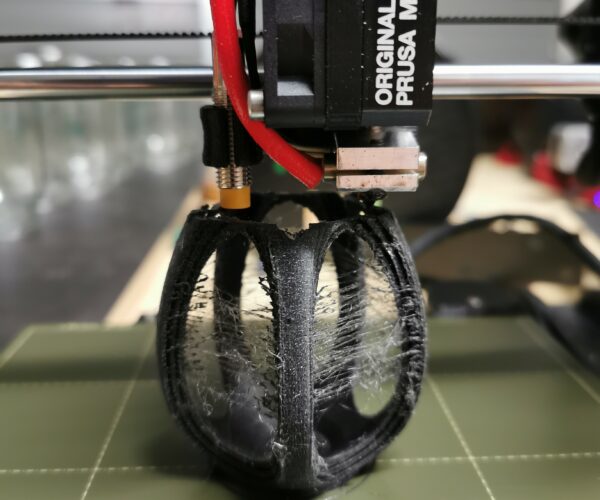

So I went on to try a different test for my mini but the stringing is horrific to say the least!

Retraction, how much should i dial it up by?

Are any other settings relevant to help eliminate stringing.

This file was printed with pursament pla and on 0.07 layer height from memory, sliced through prusaslicer.

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Stringing! how to fix that?

You can try to set lower temperature and slower print speed from what I searched.

RE: Stringing! how to fix that?

What are you using to slice the model? Prusaslicer does not have coasting and this a bowden printer, so your rely on linear advance if supported by the mini firmware.

I would download a stringing test model and try to calibrate as discussed above, adjusting the print temperature. Printing speed should not matter that much, but bridging speed( or movement speed when not printing ) does.

When troubleshooting stringing issues try to determine where the blobs you see in the string are created. If they are created on the begging of a move you can use coasting to reduce it. if they are before the nozzle lands, at the end of a move, wipe will help. The size of the blobs can also provide guidance as to whether you are retracting too much or too little.

RE: Stringing! how to fix that?

I assume the main issue is the little time your layers have to cool down. Like @peanutbutte7 suggested you could reduce the speed, but simply printing more objects at the same time is more effective and will do the trick as well. 😉

@minos197 confuses travel speed with bridging speed. But increasing travel speed could actually help. Also, coasting and linear advance are features to improve edges and seams. Bad settings will increase stringing, but if you don't have issues with the seams, you don't need to tweak those settings.

Lowering printing temperature will reduce stinging, but it also weakens your object. Same is true for more cooling.

If you want to tweak with your retraction settings: The retraction distance on a Bowden extruder is usually between 2 and 8mm and the retraction speed between 35 and 45mm/s. Start with low values, because too high values will introduce blockages.

RE: Stringing! how to fix that?

@lichtjaeger

This is useful info in one place, thanks.

RE: Stringing! how to fix that?

Thanks for the input guys n gals, its appreciated.

After reaching out to support and waiting a bit for an email back they had me strip this pain in the arse printer down again rebuild the hot end and after 2 jams I rebuilt it differently to the instructions (changed the method supplied) and I have it printing again and after a test print of the same file in the original picture 3d fillies filament printed great very very minor stringing! Granted it was printed at 200 degress and not 215. The print still "failed" as the printer printed the parts but they were fused together and did not turn. The file is 3 "eggs" one inside the other and if printed correctly they should turn independently of each other.

Im about to try again with prusament, fingers crossed.

I will slow the print speed slightly and slightly and report back.

Again a massive thank you to all who have responded.

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Stringing! how to fix that?

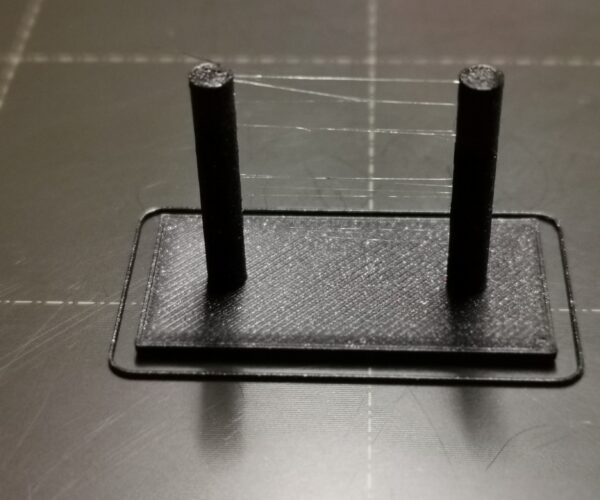

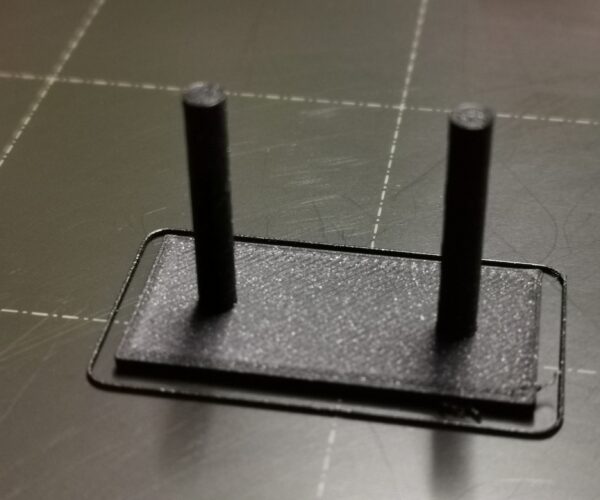

I printed a stringing test and the stringing now is defiantly reduced. The first pin that prints has small blobs on the inside edge that I want to fix, I will have a play around with coasting and linear advance.

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Stringing! how to fix that?

Do after spending 3 hrs on the chat with support. I went from this

To this

Very happy.

Retraction now at 3.8

Idler tension increased

Retraction on layer change enabled.

The stringing test came out great. I'm now reprinting the resliced torture egg to see how it goes

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Stringing! how to fix that?

Care to summarize their recommendations for the benefit of others who may be looking for a solution? Glad you got it working.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Stringing! how to fix that?

Care to summarize their recommendations for the benefit of others who may be looking for a solution? Glad you got it working.

Retraction now at 3.8 - slowly increased this over prints

Idler tension increased - 1/2 a turn per print

Retraction on layer change enabled. This gave instant results. It stopped the blobs.

Make small changes and test the settings. Had to revoke some changes, but ultimately it's going great now

Respect the fact everyone is entitled to have an opinion, you dont have to like it or hate it, just accept its theirs and not yours and you will be ok!

RE: Stringing! how to fix that?

Can I ask what retraction speed you set??

Many Thanks.

RE: Stringing! how to fix that?

@m8harry

Sorry for the dumb question, but I am having same issue with my mini! What does "idler tension increased - 1/2 turn per print" mean. is that a setting or something you are doing to the printer?

Thanks!

RE: Stringing! how to fix that?

Hi John-r9,

Idler tension refers to the actual printer. It's the tension on the idler wheel within the extruder. If you look at the following link and scroll down to the bottom there's a picture of the idler adjustment screw location. You need just enough tension to properly grip the filament without damaging it.

https://help.prusa3d.com/en/article/clicking-extruder-under-extrusion-and-clogging-mini_112011

Good Luck,

Paul C.

RE: Stringing! how to fix that?

Hi,

I have been printing with my MINI for quite a few hours now, and I can't get rid off of my stringing issue. Lowering temp, increasing retraction and retract on layer change helped a bit, but didn't solved the issue.

So when I see this, I start thinking that I have some issues with my printer.

https://www.reddit.com/r/prusa3d/comments/ivj4wj/fedex_guy_to_3dbenchy_in_2_12_hours_this_thing_is/

To illustrate:

(first print ever, with the provided GCode in the USB stick and prusament PLA sample)

(another print, sliced with prusaslicer, 5mm retractation, prusament PLA)

As you can see, there is quite a bit of fine stringing that I can't manage to fix.

Anybody with the same issue?

Another stringing issue on the mini

@marklinmax

I know this is an Old thread but still relevant for me anyway.

did you ever get rid of the stringing, and what parameters did you change in prusaslicer?

Another stringing issue on the mini

Hi @buenso80,

I haven't yet!

I got the printer returned to the factory where they did some tests, including some prints, which I have to say came out really great.

So it led me to suspect other factors to which the printer might be particularly sensitive, like the power-supply or my own home electricity.

Anyway, I haven't had much time to conduct further investigation on that lately, so I just take more time to clean the prints afterwards.

Stringing....

So, I bought two rolls of Jesse filament. Love their colors. First roll printed really nice, but had some stringing. I tried temperatures, retraction, etc. Got it minimized but still had some stringing. Not a huge deal, quick shot with heat gone and it was gone. Prints looked fantastic. Second roll, right out of the package was perfect. No stringing at all. None. Beautiful. My conclusion is that probably varying degrees of moisture. I need to get a dehydrator or filament dryer and dry each roll really good before it goes on printer. I really think a lot of the stringing issues people have is because of wet filament.

RE: Stringing! how to fix that?

Hi @buenso80,

I haven't yet!

I got the printer returned to the factory where they did some tests, including some prints, which I have to say came out really great.

So it led me to suspect other factors to which the printer might be particularly sensitive, like the power-supply or my own home electricity.Anyway, I haven't had much time to conduct further investigation on that lately, so I just take more time to clean the prints afterwards.

Sorry to bump an old thread again, did you ever figure this issue out? I've also had minor stringing (not as bad as yours) since I got the printer.

RE:

This thread goes back a long way, I guess its because stringing is a problem that never really goes away.

My recent experience using Polymaker PolyCast filament, an expensive specialty material directed at the market segment using 3D printed models for investment casting. The basic polymer is PVB, with added modifiers.

Right out of the box, after a short drying cycle, I found myself able to print superb quality prints. I produced several beds of prints spanning a 12 hour period with the filament roll adjacent to the printer inside Prusa Enclosure. Then I unloaded the filament and put it into dry storage.

The next day I started on the next bed, a different model. it was a long one, spanning 18+ hours. At the start, it printed just as well as previous, but sometime after I went to sleep, the extruder clogged and the printer happily just air printed away (no birds nest).

Tried another nozzle. It also clogged after a shorter time span. But this one also produced a lot of stringing, not previously seen with this material.

So, I dried it - again - 6 hours at 55C (PrintDry dryer).

So today, to save on usage of the expensive filament, I find myself running stringing test prints, and adjusting slicer params as I go.

so far: retraction is up to 3.0 mm, lift z up to 0.6 mm, temp down to 205 C (from 215 C), Layer height up to 0.15 (was 0.1) I am printing direct from the dryer, which is operating,and I am on my second pristine new nozzle. And it's STILL stringing. But less so than earlier.

The model I am printing is of a figurine, which is to be cast in phosphor bronze, needing as fine and unblemished a surface as possible. The fact this material can be smoothed using IPA is useful for the next step after printing. But the need to remove blemishes caused by stringing can mar the surface (and ditto for supports).

My goal is to get the material printing just like it did the first day: no stringing, and no clogging of the nozzle.

Doesn't seem unreasonable to me.

I'm starting to pull my hair out on this.

Who has experience of this phenomena can provide some guidance ?