PTFE Tupe Pops out of Fittings

I am not quite shure what the problem is. I have my mini since begin of december. I was printing a whole spool of galaxy black PLA prusament, without any problem. Then I changed to Jet Black. Very soon after, I had a jam in the extruder. After disassembling the extruder. I tried to reprint the part. Next thing that happend, the PTFE hose poped out on the extruder fitting. I checked the nozzle and tried a cold and hot pull. Also pushing out filament trough the heated nozzle worked well. So I assembled the extruder again and used a new brass olive to refit the PTFE Tube. I succeeded to print a small object, but after the next print, the same happend again. So I ordered new PTFE Tube (extruder to Hotend).

Actually I have no plan if replacing the PTFE tube, the problem will go away, since it seems, there is a lot of pressure in the PTFE Tube between hotend and extruder.

On the print it seems that the the printer has trouble to get out enough filament. Actually I have no plan how to solve the problem. Since the mini is using a very proprietary PTFE Tubing system, replacing item is not so easy because the are only available trough prusa shop.

Any idea what I should check to solve the problem ?

RE: PTFE Tupe Pops out of Fittings

I gave up as, I was not having more brass fittings. And Prusaslicer was by itself sometimes setting PLA with low temperature (showing my PLA profile, but used Prusa's PLA profile) , so it torn it few times out. Original extruder did it few times and later also BondtechExtruder did it too.

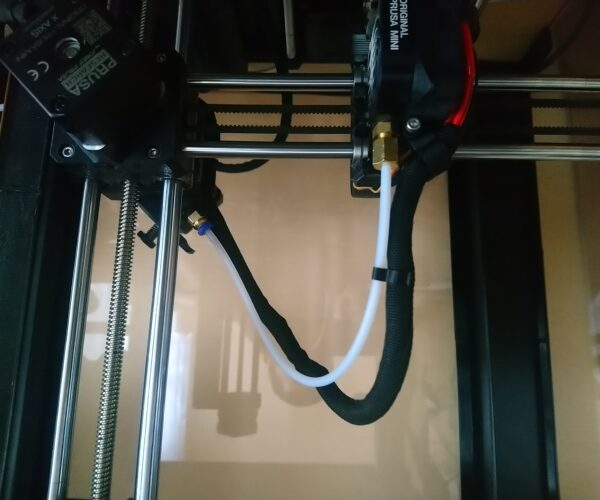

So, now I have this setup and quite happy. It is already like 3 cm shorter as original, but keeping it in mind, is ok. Yes, I ordered replacement from Prusa, but same happened until I started to use this one.

RE: PTFE Tupe Pops out of Fittings

@john-doe-5

Hi

so I see you are using now the bondtech extruder. Did you use the settings for E-Steps they recomend (M92 E415). I will try to shorten the PTFE Tube since in the meantime it got a bit worn out, I have to do it anyway. I ordered some new ones from prusa, they are only available as complete sets. I succeded to order the olives only over ebay, but the only get US delivered only, so I had to use a mail forward service.

I have seen people using standard couplers instead of the proprietary ones with M8 tread and capricorn tubes.

Meanwile I changed to a bondtech extruder too. But with the same effect. I also got now clicking in the bondtech extruder what I never got in the orginal Prusa extruder.

So next step I will shorten the PTFE like you did. I will aso try to raise the temperature for the PLA. If this all not works, changing the heatpipe to the bontech will be the next thing.

Meanwile I hate boden design.