Printing TPU problem

I just assembled my printer 2days ago Trying to print TPU it keeps jams and clogged with every solution i do

i try prusa slicer and cura i print in speed of 15 up to 40 the temps I try from 240 down to 210 with no luck

any help will be appreciated

RE: Printing TPU problem

TPU can be quite a pain. Which TPU are you using. What are the temp specs for it?

Do other materials print easily?

What are your retraction settings? I experienced (on other printers) that (too much) retraction can cause trouble if you retract too much or too often (e.g. many short lines being printed with retraction between those). Thus the feeding gears grind too much on the filament, decreasing it's diameter and reducing the grip of the feeding gears. You could test this by trying to reduce or stop retraction. An other way would be printing a more massive test part (like a simple cube) to see if jamming occurs there as well.

RE: Printing TPU problem

I've been printing a lot of TPU recently. Here's what works for me. I'm using standard SainSmart TPU which has a durometer rating of 95A - on the stiff end of the TPU range. I wouldn't recommend anything softer until you master 95A. One key to printing TPU is a consistent flow of plastic through the hot end. I set *all* of my speeds to 20mm/sec so that the flow is consistent as possible. With a Bowden setup, there is a lag between the extruder gears advancing and the pressure building in the hot end. If you change speeds all the time, the flow of TPU out of the hot end becomes unsynchronized with the g-code. Consistent speed for every operation negates this. Only your travel speed should be different and it should be as high as possible.

Most people say to disable retraction for TPU. I actually found that a little retraction (2mm) helps reduce stringing on my prints. This goes against conventional wisdom and against everything I said in the previous paragraph, so you might want to try it both ways. It works for me, so I haven't taken the time to re-examine retraction yet. (I've also heard you should disable z-hop, but I haven't tried this yet either.)

Be careful using the PrusaSlicer filament profiles for any filament besides Prusament. Occasionally I've found them to be quite off. Specifically, the profile for SainSmart TPU is about 15C too hot (way above the top end of SainSmart's recommended range) and resulted in bubbly prints until I noticed it and dialed it down.

Finally, make sure you keep your TPU dry. It's much more hygroscopic than PLA, so you may have to take more precautions that you are accustomed to.

RE: Printing TPU problem

@pogopilot

Thanks for the advice! I read it and it makes sense. I'm very new to all this stuff. Right now I'm just using the Fillamentum Flexfill 98A profile with standard SainSmart TPU. I found the proper temp of 220 using a temp tower. Seems the temp was my first major problem I didn't know that both too hot and too cold would cause stringing. Print seems to be printing pretty good. No real stringing but there are sometime little bumps when the nozzles cross boundaries(I think that's what it's called). I'm going to test your suggestion of using the same print speed for all. I do see retraction is being used in this profile... Might need to look at that next

RE: Printing TPU problem

@darrindevine

I have gotten Filimentum TPU to print with Sainsmart settings

--------------------

Chuck H

3D Printer Review Blog

RE: Printing TPU problem

@cwbullet

Thank for the feedback. I have both Fillamentum Flexfill 98A TPU and Sainsmart filament. Sainsmart is working fairly well now and I haven't tried the Filimentum yet. The raw Fillamentum Flexfill 98A filament seems harder than SainSmart so I expect it should print easier. But IDK 🙂

RE: Printing TPU problem

Has anybody tried printing with the colorfabb varioshore TPU? Having a lot of trouble with the settings - not sure where to start. Should I look at upgrading hardware? Bondtech dual extruder.

Current setup: stock Mini+, 220 degrees, 2mm retraction, 0.2mm lift Z, speed 20mm/s

RE: Printing TPU problem

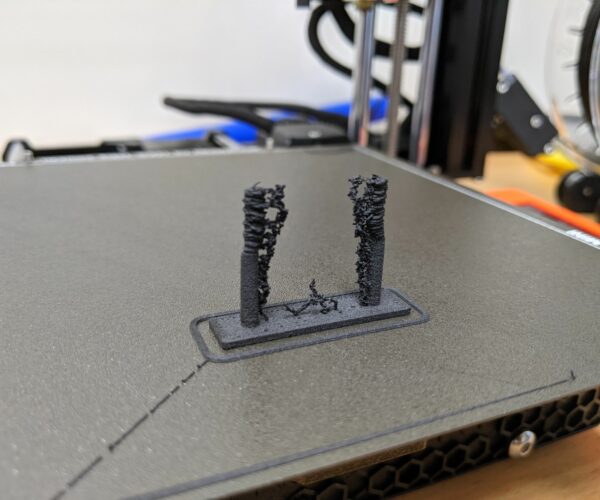

Those look reasonable but TPU is touchy stuff. I noticed your picture shows a broken line to the surround ring - your bed temperature may be off (50 C seems to work well for me), and you may need to change your extrusion multiplier for each brand of TPU (Dr Vax on youtube has a quick and easy tutorial on how to do this; it's easy, and other youtube-ers have similar videos).

The lower parts of the legs look pretty rough. First thing I'd try is to set the first layer to 5 C above the *middle* range the manufacturer recommends, i.e., if they say 200-230 C, I'd start with the first layer at 215 + 5 = 220, and back to the middle range temp (215) for the others. Next, I'd probably reduce the retraction a bit - maybe 1.5 mm? I can't tell if that's causing the holes in your print, but when I had retraction set too high I got some odd-looking holes in thin parts of my prints.

Another thing worth trying is setting the layer height to a lower value - either 0.15 or 0.10. These are referred to as Detail or Quality, but for TPU I find them necessary almost all the time, even for "test prints". Finally, if you get a part design that works OK for you in TPU, I suggest using it, instead of a temperature tower, when adjusting TPU settings. I use temp towers when I get new filaments but won't do that for TPU now - the towers just don't seem to give me an accurate feel for the proper settings.

RE: Printing TPU problem

I just want to know How do I get good TPU prints?

RE:

I just want to know How do I get good TPU prints?

Optimizing the feed rate. It is often best to use a consistent feed rate that is slow when 3D printing with flexible filaments. ..