Day 1 - sample whistle lost adhesion with 3 minutes to go

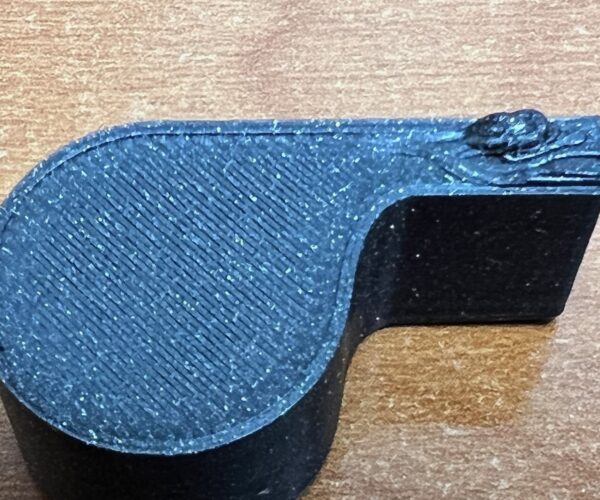

After first layer calibration I printed the PRUSA logo. I think it looked ok. Then I tried to print the whistle. The whistle was broken loose from the build plate with only about 3 minutes remaining. This is using the prusament PLA that was shipped with the printer without adjusting any settings other than z-axis during calibration. Printing on the textured PEI plate with no glue. Surface was clean and is just out of the box. Can anyone take a look at these sample photos and spot what might have gone wrong for the whistle to lose adhesion to the plate at the very end? It printed enough to work though. I'm just trying to determine what might need to be adjusted. The room temperature was around 20°C (~68°F).

Thank you, Rusty

Top of Prusa logo

Bottom of Prusa logo

Thank you for providing pictures of the underside. It looks like your first layer Z calibration is off a little.

At the end of the calibration you are aiming to print a single layer *sheet*. It should be possible to peel it off in one and fold it without the threads seperating. If it breaks into lines it is too high, not squished enough. If it is a single sheet but with wavy lines or drag marks on it you are too low.

If you find it tricky, post a picture of your first layer and we'll diagnose further.

Cheerio,

RE: Day 1 - sample whistle lost adhesion with 3 minutes to go

Thank you for the feedback. I will try adjusting z height tonight. I am scared of crashing the nozzle into the plate. I'll just have to be careful. -Rusty

You get some warning as the layer is scraped almost invisibly thin before the true crash.

If you are worried, post a picture of your first layer calibration still on the print sheet.

Cheerio,

RE: Day 1 - sample whistle lost adhesion with 3 minutes to go

Also, PLA on texture has been reported with mixed success.

I use gluestick with PLA on texture with great results.

Just another possible thing to consider.

Prusa Mini+ kit. BondTech extruder. FW 5.1.2

Prusa MK3S+ kit. Stock. FW 3.11.0

Prusa MK3S+, used. Stock. FW 3.13.3

RE: Day 1 - sample whistle lost adhesion with 3 minutes to go

Most new users are somehow reluctant to go low enough with their first layer calibration. I guess 50% of posts here can be answered with "get your live right", followed by "clean your sheet with hot water and soap"...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Day 1 - sample whistle lost adhesion with 3 minutes to go

Yes, it is a bit scary reducing your first layer height. But it works. After seeing some advice on an instructional video, I also asked PrusaSlicer to make the first layer 0.3mm, up from 0.2. This seems to produce a first layer more reliably and consistently. Do give it a try. I’m not sure if there is a downside but it works for me. .

Stay with 0.2mm first layer, thicker layers don't get squished hard enough with a 0.4mm nozzle.

Leave playing with these settings until you have plenty of experience.

Cheerio,

RE:

Printing on the textured PEI plate with no glue

I think you will find this is key.

Some key items from Prusa website on the textured sheet:

- PLA prints with a small contact area may need a brim

- First layer can be more squished compared to smooth sheets

RE: Day 1 - sample whistle lost adhesion with 3 minutes to go

As a general rule of thumb 50% nozzle diameter as max layer height for the first layer is a good target, that is, 0.2 for a 0.4 mm nozzle.

Having said that, with proper live z calibration and a properly conditioned steel sheet I've found 0.3 to work just fine.

But as diem said, use 0.2 and get live z right, and you'll be in business!

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/