Bowden PTFE tube compresion fittings too tight

Howdy Guys,

My two minis showed up and I've had marginal success with them so far. Test prints are great, but the retraction and unloading on one of them was problematic with ASA. Looking at the tube from the extruder to the hot end, it seems the initial assembly crushed down the compression fittings so hard that they restrict the inner diameter and the "rammed" end couldn't fit through the tube. I thought I was going to break something just trying to get the two brass fittings apart. Reminds me of how my father used to tighten spark plugs- "two grunts and one swear word tight." The head of the spark plug broke off 50% of the time I'd try and remove them.

Like the spark plugs, the compression fittings only need to be hand tight plus a quarter turn to work properly.

Also noticed that the hot end was not fully seated in the carriage. Mine are about 3mm down. Loosened the set screws and pressed it up and hope it helps the extrusion. I can't recall the link, but there is a nice video showing how to do the fix in the forum somewhere.

Anyhow, does anyone the PTFE tube length from the extruder to the hot end handy? I'm replacing the tube and installing the compression fittings from the spares kit. Evidently this is something they've run into before.

RE: Bowden PTFE tube compresion fittings too tight

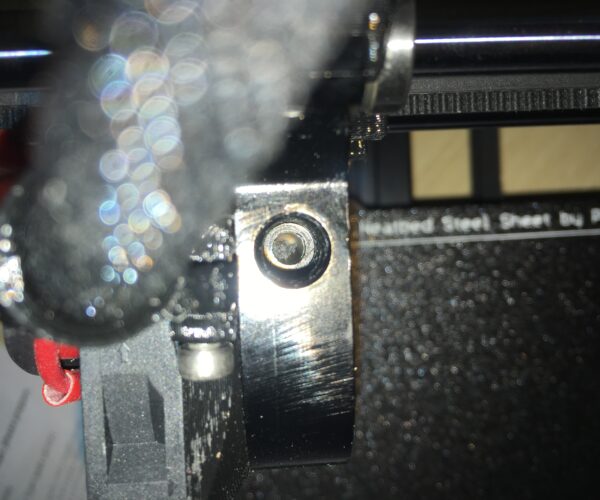

Here's a look down into the hot end with the PTFE tube removed. What's the best technique for cleaning it out? I don't want to seat the tube again with the material in there. Should I heat the nozzle, insert the PTFE tube, feed filament through, cool the nozzle, and cold pull it?

RE: Bowden PTFE tube compresion fittings too tight

@steve-f13

PTFE tube length should be 43.4 mm +/- 0.1 mm.

https://manual.prusa3d.com/Guide/How+to+change+a+hotend+PTFE+tube+-+MINI/1505?lang=en

RE: Bowden PTFE tube compresion fittings too tight

Howdy Guys,

My two minis showed up and I've had marginal success with them so far. Test prints are great, but the retraction and unloading on one of them was problematic with ASA. Looking at the tube from the extruder to the hot end, it seems the initial assembly crushed down the compression fittings so hard that they restrict the inner diameter and the "rammed" end couldn't fit through the tube. I thought I was going to break something just trying to get the two brass fittings apart. Reminds me of how my father used to tighten spark plugs- "two grunts and one swear word tight." The head of the spark plug broke off 50% of the time I'd try and remove them.

Like the spark plugs, the compression fittings only need to be hand tight plus a quarter turn to work properly.

Also noticed that the hot end was not fully seated in the carriage. Mine are about 3mm down. Loosened the set screws and pressed it up and hope it helps the extrusion. I can't recall the link, but there is a nice video showing how to do the fix in the forum somewhere.

Anyhow, does anyone the PTFE tube length from the extruder to the hot end handy? I'm replacing the tube and installing the compression fittings from the spares kit. Evidently this is something they've run into before.

I thought the same... My Mini jammed during unloading and I took the tube off and felt there was resistance at the olives...

Since then its jammed several times and I am 90% sure the fittings are too blame.. I too am going to make another one up at some point to see if its any better.

RE: Bowden PTFE tube compresion fittings too tight

@jweaver

I'll let you know. The PTFE tube length between the extruder and hotend was the one I was looking for. I did a parallel cut and it seemed to work. Used some premium PTFE tubing I keep for feeding the MK3S from sealed tubs.

I'm printing a couple of Benchies right now- one with Fillamentum ASA and the other with Prusament ASA. I'll see how the unload goes when they're done- if they stick to the textured plate, that is.

Steve

RE: Bowden PTFE tube compresion fittings too tight

Hi, I had the same issues with unloading the filament due to the tight fittings in PTFE tube, see my solution here https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/problems-unloading-filament-jamming-in-ptfe-tube/#post-196489

RE: Bowden PTFE tube compresion fittings too tight

Hi, I had the same issues with unloading the filament due to the tight fittings in PTFE tube, see my solution here https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/problems-unloading-filament-jamming-in-ptfe-tube/#post-196489

My plan was to do exactly the same thing... i have a 0.1mm drill set so have drills from 1mm to 5mm. So i was going to try 1.8mm and go from there.... glad to know it works.. gives me some inspiration to try now,

RE: Bowden PTFE tube compresion fittings too tight

Wow. Thanks for the hack. I've had the same problem loading and unloading. Will give this a try soon!

Steve